Hydraulic Gantry Shear for Metal Cutting

| Hot-selling model | SLY-200T |

| Max. cutting force | 200t |

| System pressure | ≤25Mpa |

| Bin size | 700*1600*2300mm |

| Blade length | 1200mm |

| Capacity | 2.5-3t/h |

| Shearing force | 4-6times/min |

| Power | 2*18.5kW |

| Weight | 11t |

You can now ask our project managers for technical details

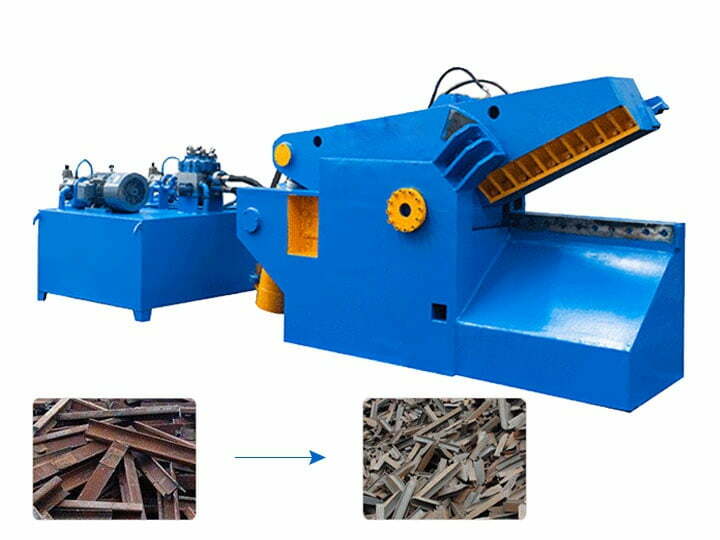

Shuliy gantry shear(hydraulic metal shearing machine or sheet metal shear) is mainly used for cutting off large or long scrap metal materials. It has a capacity of 4-6 times per minute to shear scrap metal.

This metal cutting shear adopts cold cutting, cutting scrap metal into 20-30cm, and the output ranges from 2.5-30t per hour.

The hydraulic metal shear is always equipped with a conveyor for scrap metal feeding. It’s suitable for various shapes of scrap steel, scrap iron, dilapidated gasoline barrels, and various metal structural parts.

Besides, it can handle large quantities of scrap and is also very friendly to the environment.

Thus, the scrap metal shear is widely used in various metal recycling processing plants, scrap car dismantling sites, smelting and casting industries, etc. If interested, welcome to contact us for more details!

Advantages of hydraulic gantry shear

- This machine adopts hydraulic pressure for working, low noise, stable operation and long service life.

- Shuliy metal shear machine adopts electric control, easy and safe to use.

- The machine is the strongest shear force from Shuliy, which can handle heavy-duty metal scrap. Its capacity is also very powerful.

- It has a wide range of metal scrap processing, like construction rebar, scrap car shells. It has very strong practicality.

- There are various models of machines, and the output ranges from 3t to 250t.

- The size of finished products can be set. Generally speaking, the finished product size is 20-30cm.

Technical parameters of heavy duty metal shear

| Model | SLY-200T | SLY-400T | SLY-600T | SLY-800T | SLY-1000T | SLY-1250T |

| Max. cutting force(t) | 200 | 400 | 600 | 800 | 1000 | 1250 |

| System pressure(Mpa) | ≤25 | ≤25 | ≤25 | ≤25 | ≤25 | ≤25 |

| Bin size(mm) | 700*1600*2300 | 5000*1300*500 | 5500*1500*700 | 6000*1700*800 | 6000*1900*1000 | 8000*2100*1500 |

| Blade length(mm) | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 |

| Capacity(t/h) | 2.5-3 | 4-5 | 8-10 | 15-20 | 20-25 | 25-30 |

| Shearing force(times/min) | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 |

| Power(kW) | 2*18.5 | 2*45 | 3*45 | 4*45 | 5*45 | 6*45 |

| Weight(t) | 11 | 19 | 30 | 38 | 60 | 88 |

We have various types of hydraulic metal shears for sale, and the capacity is 2.5-30t per hour. If you’re looking for a metal waste recycling solution, please feel free to contact us. We’ll provide the best suggestions to you.

For example, if you want to cut construction steel waste with a capacity of 4-10t per hour. Also, your budget is sufficient. Then the SLY-800T gantry shear will be the best choice for you.

If you want a detailed solution, welcome to contact us at any time for more!

Applicable raw materials & applications of hydraulic gantry shear

This sheet metal shearing machine is mainly suitable for cutting various metal scrap, such as:

Solid scrap iron, light and thin scrap steel, scrap car shells, bulk light metal structures made of steel, scrap steel for production and living, various plastic nonferrous metals (stainless steel, aluminum Alloys, copper materials), construction scrap steel, large irregular steel structures, steel pipes, steel plates, channel steel, I-beams, steel bars, etc.

After shearing, it’s for easy transportation and suitable for compression baling into furnace charge.

Shuliy electric metal shear is ideal processing equipment for:

- Steel plants

- Non-ferrous metal smelting industry

- Precision casting industry

- Raw material manufacturers

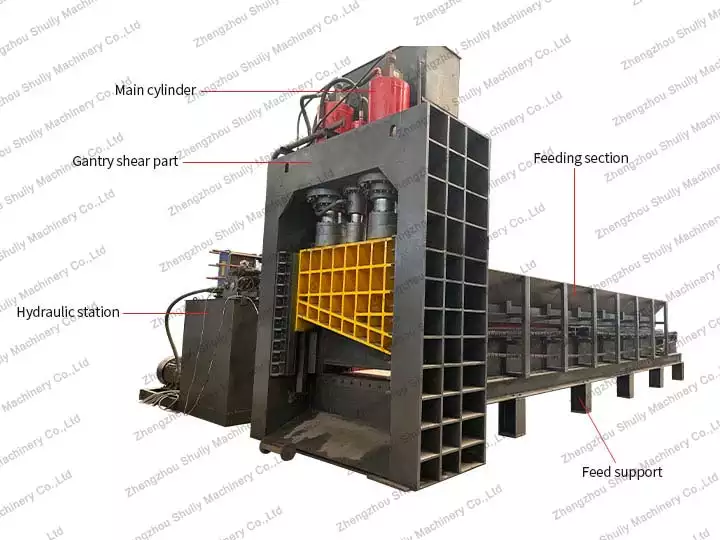

Structure of the heavy duty metal gantry shear

This machine is made of bin, head and cutter.

- Bin: store all kinds of metal scraps. Sometimes you need the loader for loading scrap metal, convenient and fast.

- Machine head: a vertical frame with a hydraulic lever on top, which is pressed down when working.

- Blade: an important tool for cutting metal scrap.

- Different machine models have different blades.

- The blades belong to the wearing parts, which can be properly equipped with a few more sets.

How does Shuliy metal shearing machine work?

The workflow of the machine can be described as simple.

- First, use the loader machine to load the material.

- When the metal scrap reaches a certain amount, the loading can be stopped and the bin door can be closed.

- Then, the hydraulic rod starts to work.

- There is a hydraulic lever at the back of the bin, pushing the metal scrap forward.

- The hydraulic lever at the head of the machine is responsible for pressing the material.

- Finally, the cutter falls to shear the scrap, and the whole process is completed. Then repeat the whole process.

Why shearing scrap metal for recycling?

- Higher selling price. After cutting, it can be packed and easy to transport. When sold, the density is greater and the price will be higher.

- Further processing and utilization. After shearing, various metal wastes can be put into metal processing plants, smelters, etc. It’s for further processing to create more profits.

- Convenient recycling of scrap. If the waste is not sheared, it will be difficult to process and recycle. Shearing just solves this problem.

Precautions in operation and blade replacement

Check this article to know more details: How To Use And Change Blades Of Scrap Metal Guillotine Shear?

How about heavy duty gantry shear price?

The machine price is one of the most important things to consider, and is mainly affected by the following:

- Shear force and shear capacity. The higher the shear force, the more types and sizes of metal scrap the equipment can handle. Accordingly, the price will be higher.

- Hydraulic system and motor power. Higher power hydraulic systems and motors provide more shear force and higher efficiency, but also increase equipment costs.

- Blade quality and life. The use of high hardness, high wear-resistant materials made of blades costs more. However, it can significantly extend the service life of the equipment and reduce maintenance costs.

- Brand and after-sales service. The gantry shears of famous brands usually have guaranteed quality and perfect after-sales service, so the price is relatively high.

- Customized demand. If you want to customize the machine(like special size, extra features or enhanced durability), the machine price will be higher than the standard model.

Successful case: hydraulic metal shear for sale to Bahrain

In July this year, a customer from Bahrain asked us for information about the shears. According to his request, our sales manager recommended this gantry shear to him.

Not only can it handle a large amount of metal scrap, but also the shearing force is the strongest that can be handled. The machine is stable and also can be used for a long time.

After understanding the machine, this Bahraini customer was very happy and we signed an agreement. We also talked about sending the machine by sea to his place.

Further metal waste recycling solution

After shearing, you can further bale waste into waste metal cubes with the metal baler.

Are you looking for an efficient metal recycling solution? If yes, contact us now, and we’ll provide the best solution to benefit your business.