How to choose and install alligator shear blades?

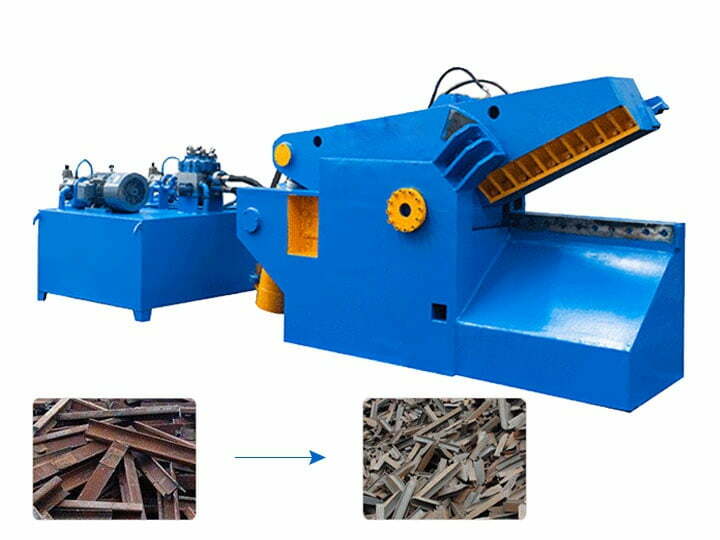

Hydraulic metal shears are widely used in cold shearing of steel waste. The metal shear is suitable for various raw metal materials including round steel, square steel, angle steel, plate steel, steel pipe, waste reinforcement, small pressing block, steel plate, etc. Because of its simple design structure, low failure rate, high shear pressure, low maintenance cost, long service life, the hydraulic metal cutting machine is an ideal product in the metallurgical industry. It is known that the alligator shear blades material is the key to the blade performance, also the core of the equipment. The scrap metal shearing machine can meet the strict requirements for the finishing section of the plate. The cut of the material to be cut is flat and smooth, burr-free. This article mainly introduces the blade types and installations that users are concerned about.

Should the alligator shear blades be as hard as possible?

The main cutting object of the blades is all kinds of hard metal materials, so the hardness of the blade must be sufficient. In addition, the wear resistance of the alligator shear blades is also important because they are used frequently. The hardness and wear resistance of the shear blade mainly depends on the heat treatment in the machining process. When cutting iron plate, the higher the hardness of the blade, the more wear-resistant it is. However, it should be noted that too high hardness can lead to brittle blade edge, and blade fracture is easy to occur when shearing too high hardness or thick iron plate. Therefore, the heat treatment of the shear blade is the key to determining the hardness, and also directly affects the performance of the blade.

The types of alligator shear machine blades

The standard material of alligator shear blades is 9CrSi, and other materials generally include T10, 6CrW2Si, Cr12MoV, H13, alloy steel, and so on.

1. For low alloy tool steel: the commonly used material of the blade is 9CrSi, etc., and the heat treatment hardness of the blade is within the range of HRC58-62 degrees. It is specially used for cutting stainless steel, which is suitable for cutting hot-rolled plates, stainless steel, medium, and thick plates.

2. Carbon bonded tool steel generally adopts 65, 75 steel, T8, T10, and other materials. The heat treatment hardness of the blade produced by this material is within the range of hrc57-59 degrees. It is suitable for the recycling and shearing of ordinary low-carbon cold-rolled plates, ordinary A3 plates,s and waste. This feature is low cost and appropriate product price.

3. For alloy tool steel, the blade material of plate shear can be 4Cr5MoSiV1 (h13k), H13, etc. The blade of this material is used for hot rolling billet, hot shearing medium, and thick steel plate, which is characterized by high-temperature resistance and difficult annealing.

Blade specification: standard blades are available from stock, and non-standard cutting tools can be customized according to specific requirements.

How to install the blades of hydraulic alligator shearing machine?

The installation steps of alligator shear blades

- Clean and measure

Carefully clean the locking area and install the cutting tool on the turret. Then, measure the deviation of the metal shear blades on the stroke with a length of 100mm, which shall not exceed 1mm.

- Check the vertical condition

Generally, the method to detect whether the scrap metal shearing machine blade is vertical is to check the generated chips. If the chip produced by the workpiece flows to one side in the form of long filaments, it may be that the crocodile shear blade is installed incorrectly. Another phenomenon is the early wear at the fillet of the cutting blade. It indicates that one side of the blade is under more pressure than the other side.

- Check the cutting condition

During installation, a slight collision will also cause deviation. Therefore, check the cutting conditions of the cutting tool as soon as possible after installation, which can help to identify and prevent serious metal shear blade failure.

- Inspect relative position

Another major consideration is the position of the cutting edge relative to the workpiece axis. Among them, common problems are early wear and sudden failure, poor chip form, poor side roughness, and vibration.

- Notice the height of the alligator shear blades

When the blade is installed slightly above the center, the tangential force can act on a larger blade area. This will increase the strength of the cutter blade and position the blades firmly in the slot.