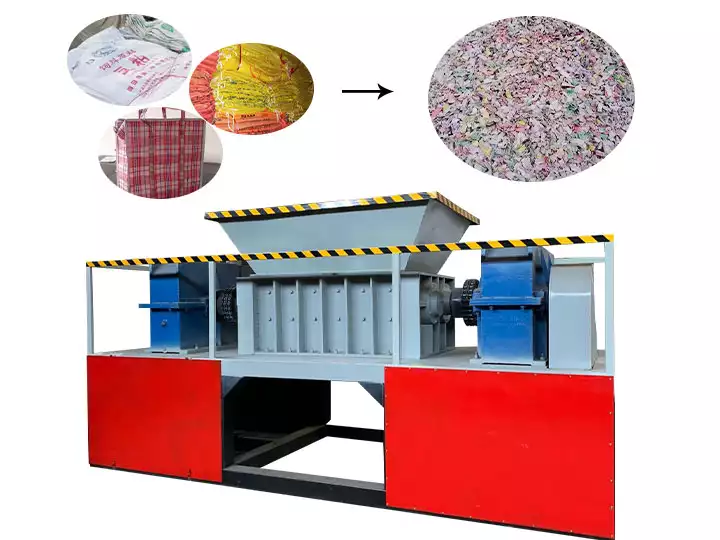

Double Shaft Shredder for All Wastes Shredding

Industrial Shredder | Twin Shaft Shredder

Machine brand: Shuliy

Machine name: two shaft shredder

Popular models: SL-400, SL-600, SL-800, SL-1000, SL-1200

Capacity: 0.5-25t/h

Materials to be shredded: metal, plastic, wood waste, electrics, and others

Optional configurations: conveyor belt, stand and screen

Advantages: high efficiency, customization and various options

This double shaft shredder(also called twin shaft shredder) is specialized in shredding various materials, such as metal, plastic, household garbage, wood, etc. into small pieces for recycling. It can handle waste of 0.5-25t per hour.

Shuliy twin-shaft shear shredder features wide applications, strong shredding power and cost-effectiveness. It is very popular in the waste recycling industry.

Our 2-shaft shredder has been exported to Malaysia, Italy, Indonesia, Iran, Uzbekistan, Romania, the USA, Australia, Peru, Russia, and so on. If you’re interested, come and contact us for more machine information.

What can be crushed by Shuliy industrial shredder?

Our double shaft shredder is all-purpose and can shred all kinds of waste. Now, I will introduce what wastes can be shredded.

- Fabric: all kinds of textiles, rags, clothes, bed sheets, and covers.

- Scrap metal: iron wire, car shells, aluminum scrap, iron scrap, lead plate, rebar, etc.

- Plastic waste: plastic PET bottles, plastic films, plastic pallets, etc.

- Construction scrap: steel pipes, steel, pipe fittings, and framework.

- Scrap tires: rubber tires, car tires, truck tires, bicycle tires, and vehicle tyres.

- Waste appliances: TV sets, washing machines, refrigerator shells, freezer shells and gas stoves.

- Electronic waste: cell phones, circuit boards, cables, copper wires, etc.

- Various containers: plastic cans, plastic drums, iron drums, packaging boxes, drums, aluminum cans, etc.

- Wooden category: wooden pallets, forklift brackets, and other waste wood.

- Others: motorcycles, kitchen waste, household waste, animal carcasses, RDF derivatives, medical waste, biological straw, garden waste, rubber head waste, paper mill twisted rope, etc.

As long as you want to shred the waste, our shredder can help you do it.

Features of double shaft shredder

- Output of 0.5-25t/h. Our industrial shredder can process waste ranging from 0.5-25t/h, which is efficient recycling.

- A wide range of applications. Shuliy twin shaft shredder can shred scrap metal, plastic, electrics, wood materials, household garbage, etc.

- Two excellent motors. The double shaft medical waste shredder can provide efficient power to ensure the machine works stably.

- Suitable for indoor and outdoor work. Shuliy digital shredder has low noise and can work both indoors and outdoors.

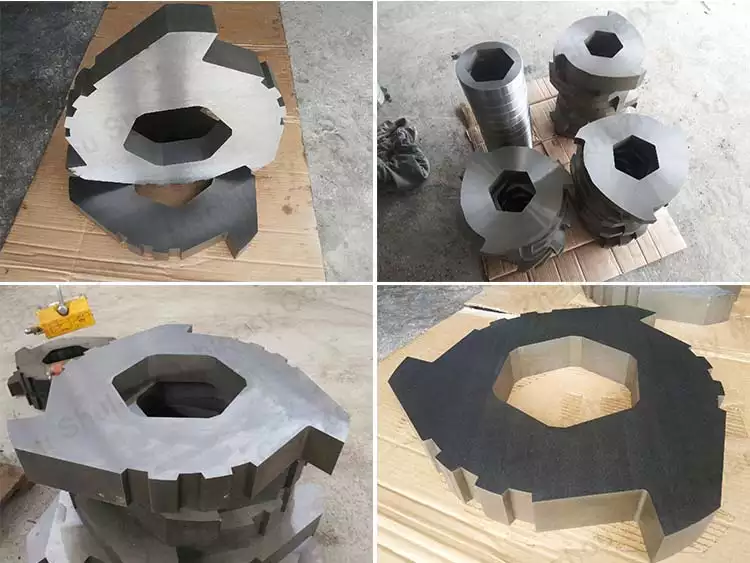

- Removable blades. The blades on the double shaft can be dismantled for easy maintenance, which greatly shortens the maintenance time.

- Optional blade number and material. You can choose the suitable blade number and materials for waste recycling, which provides the best solution for shredding different materials.

- For blade no., if you want a small capacity(like 900kg/h), then the machine equipped with 20pcs of blades is enough.

- For blade materials, 55SiCr is good for shredding wood and plastics, 9CrSi is good for crushing rubber and metal, and H13 is better for metal shredding.

- Screen-free design at the discharge port. This double shaft shredder design greatly improves the shredding efficiency.

- Independent PLC control system. When using the rubber tire recycling shredder, it’s safe and convenient.

- Optional power system. The bulk shredder can use a motor or diesel engine, according to the needs of your region’s flexible choice.

- Customization. According to your needs, we can customize the voltage, power, conveyor belt, stand, screen, etc.

- For large-capacity shredders, the conveyor belt and stands are equipped.

- For irregular materials, the screen is equipped.

Technical parameters of industrial dual shaft shredder for sale

Shuliy industrial shredder comes in many models, with output ranging from small to large. It’s mainly to meet your different shredding demands. The following different models are for your reference.

| Model | Power (kW) | Output (t/h) | Blades quantity (pcs) |

| SL-400 | 7.5*2 | 0.5-1 | 20 |

| SL-600 | 11*2 | 1.5-2 | 30 |

| SL-800 | 18.5*2 | 2-3 | 40 |

| SL-1000 | 22*2 | 4-5 | 50 |

| SL-1200 | 37*2 | 5-7 | 30 |

| SL-1400 | 45*2 | 8-10 | 40 |

| SL-1600 | 75*2 | 12-15 | 20 |

| SL-1800 | 75*2 | 15-18 | 18 |

| SL-2000 | 90*2 | 20-25 | 20 |

Notes to the two shaft shredder:

- Warranty period: 2 years

- Optional collocation: screen and conveyor belt

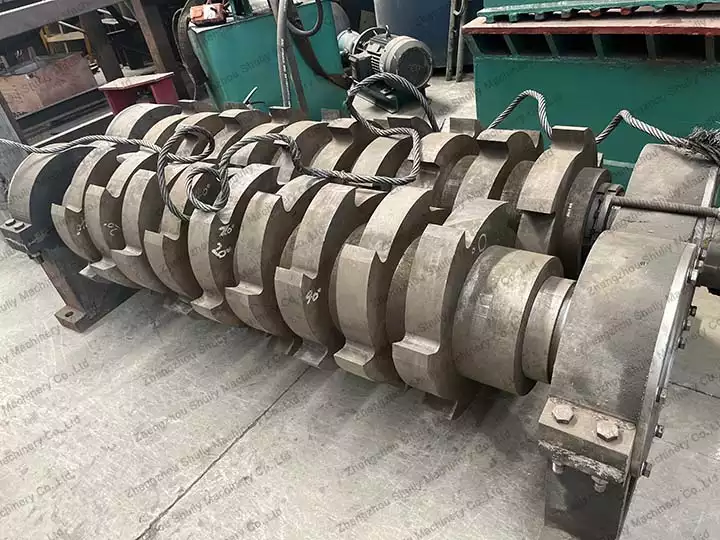

Unique double shaft shredder design

The design of our twin shaft shredder is in line with the customer’s habit of use, and it is very convenient to use.

It consists of motor( or diesel engine), reducer, hopper, discharging port and double shaft with blades.

Besides, we can also equip the conveyor belt, stand or screen for your convenient use. Depending on your actual situation, we’ll make the suitable configuration.

How does industrial shredder work?

This double shaft shredder works relying on two double shafts with sharp blades.

After entering the twin shaft shredder machine, the material is torn and sheared by the cutters in a staggered rotation. Then it’s split and broken into smaller sizes and subsequently discharged.

How about double shaft shredder machine price?

The price of the dual shaft shredder is affected by various aspects. As far as the machine itself is concerned, it is mainly the machine configuration of the reducer and the blade.

- Reducer

- Its role is to reduce the speed while increasing the output torque, but also to reduce the load inertia.

- The reducer has ordinary models and customizable models. Customizable models are certainly more expensive than ordinary models.

- Shredder blades

- In the process of material shredding, the blade is the core. Therefore, the blades’ thickness, quantity, and quality affect the machine’s price.

- Generally, the thicker the blades and the greater the quantity, the more expensive the machine.

Why choose Shuliy two shaft shredder as the top choice?

- High-quality and durable equipment quality

- Shuliy double shaft shredder is made of high-strength steel and is equipped with wear-resistant and corrosion-resistant knives.

- The equipment can handle various materials (such as scrap metal, tires, etc.) with excellent stability and long service life.

- High-efficiency shredding technology

- Our dual shaft shredder adopts an advanced slow-speed and high-torque design, which can effectively deal with various types of difficult-to-shred materials.

- It not only has high working efficiency, but also has low energy consumption, which greatly improves resource recovery and waste disposal.

- Professional one-stop services

- Shuliy provides a one-stop service from pre-sales consultation to after-sales maintenance.

- We can customize shredder solutions according to your specific production needs, such as blade no., blade material, voltage, etc.

- Complete after-sales service system

- Timely and thoughtful after-sales services, including installation and commissioning guidance, operating training, parts supply and fault repair, etc.

Contact us to start your waste recycling business!

Start your waste recycling business with Shuliy!

We offer a one-stop solution for waste processing equipment, such as double shaft shredder, metal baler, metal shear, etc.

From scrap metal to rubber tyres, we can help you efficiently convert waste into valuable resources. Contact us today for a greener way of doing business!