Metal Chip Briquetting Machine | Aluminum Chip Briquetter

| Model | SL-315T |

| capacity | 300-500kg/h |

| Density | 2400kg/m³ |

| Control system | PLC automatic control |

You can now ask our project managers for technical details

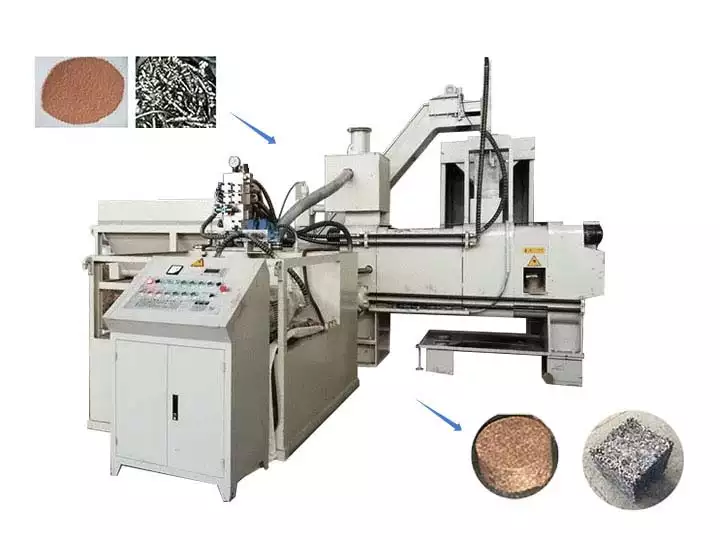

The metal chip briquetting machine is a kind of recycling machine for various metal scraps. In various steel plants, there are a lot of metal scraps and scrap metal scrap every day, so there is a metal briquetting machine to process and recycle various scraps. We have not only this machine but also the metal baler, shear machine, shredder, etc., all of which can handle metal and metal scrap machines. If you are interested, welcome to contact us.

What is a metal briquetting machine?

The automatic scrap metal chip briquetting machine(vertical metal briquetter, hydraulic metal powder press machine) is the important waste metal resources recycling equipment for briquetting various metal chips and metal powder, such as iron scraps, iron, and aluminum chips, copper and steel shavings and so on. This metal chip briquetter can cold press various powder or granular metal scraps directly into 3-15 kg cylindrical cakes for easy transportation and furnace operation. The entire briquetting process does not require high temperatures, additives, or other processes. The density of steel scrap after briquetting can reach 5-6 tons T/m³.

Why use the metal chip briquetter?

At present, most metal processing plants and steel foundries do not pay enough attention to the treatment of metal scraps and chips. Most of the metal scraps are stacked randomly, which will not only cause a waste of resources, but also cause serious environmental pollution.

Especially in some large-scale open-air metal chip stacks, most metal chips are shipped in bags or iron boxes and then sent to other places by the trolley that transports the metal chips. During the whole process, metal chips will fall in various places, causing land pollution and waste of resources. The metal chip briquetting machine can squeeze most of the scrap metal materials into a cylinder and various sizes of blocks, which can effectively reduce the waste of metal resources and reduce transportation costs.

Applications of the metal briquetting machine for sale

It can return aluminum chips, steel chips, iron powder, copper chips and other briquettes to the furnace. Replace scrap steel, iron chips, aluminum ingots, and scrap copper as raw materials to reduce burnout. This hydraulic metal briquetter machine can briquette these metal scraps into a cylindrical shape with different adjustable diameters and lengths.

This vertical scrap metal chip briquetting machine is widely used in aluminum alloy profile plants, steel casting plants, aluminum casting plants, copper casting plants, and most waste metal resource recycling stations.

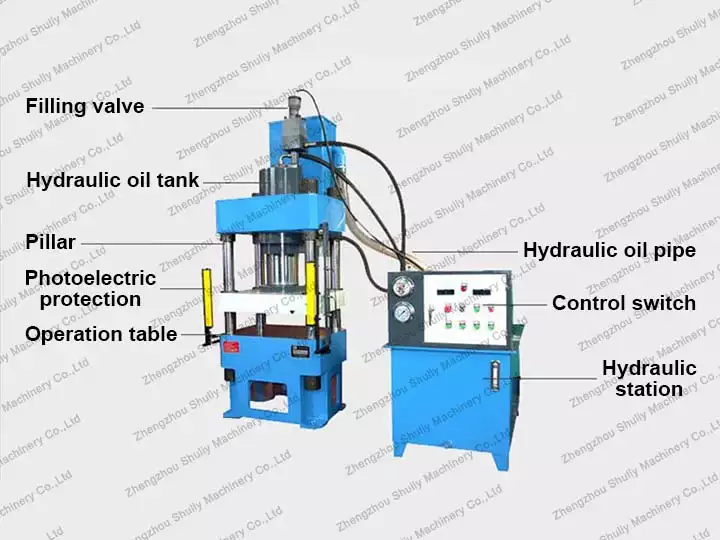

What composes the aluminum chip briquetter?

Fully automatic metal chip briquetting machine adopts an intelligent PLC control program, its main components: the mainframe is made of cast steel upper and lower beam structure, durable and never deformed.

The four hydraulic columns adopt advanced chrome plating technology, which is beautiful and elegant, safe and reliable. The hydraulic oil tank is used to store the working medium. The hydraulic oil is 46 # anti-wear hydraulic oil.

The electrical control system of the aluminum briquette machine is used to control the action of each cylinder. The hydraulic valve group of the metal chip press machine uses a high-density, large-diameter oil circuit, which has a large flow rate and fast speed.

The power system of the machine is composed of a motor and an oil pump, with high quality, stable operation, low failure rate, and strong continuous working ability.

How does a metal briquetter machine work?

In fact, this machine works mainly on the basis of hydraulic pressure to squeeze the scrap to be processed, and the power is used for electricity.

First, the metal scrap is put into the storage bin.

Secondly, the scrap enters the forming mill and is gradually formed under the constant extrusion of the hydraulic cylinder.

Finally, the scrap is shaped and the whole process is completed, producing about 4 or 5 pieces a minute. Then the process is repeated again.

Spotlights of recycle waste metal chip briquetting machine

- Fully automatic metal chip briquette production line. The aluminum chip briquette machine can be used with automatic conveying equipment. The metal chip briquette production line includes large steel chip storage silos, conveyors, air compressors, steel chip crushers, and other auxiliary equipment. As a professional manufacturer of metal recycling equipment, our machines can meet customers’ needs for highly automated production and reduce labor costs.

- Different models and production capacities. The aluminum briquette machine has wide ranges. We can choose the model and specifications of steel briquetting machines for customers according to their specific needs.

- Customization. We can also help customers customize the shapes and sizes of the final products. The metal chip briquette machine is a product that we independently design and manufacture, which is easy to use, high efficiency and stable product performance.

- Automation, low failure rate, easy maintenance.

- Cost saving, convenient transportation, and can create profit again.

- Compact structure, smooth operation and long service life.

How to use the aluminum chip briquetter safely?

- Please acknowledge the power supply used by the machine and do not plug in the wrong power supply.

- Remember to unplug the power supply when not using the metal briquetting machine.

- Do not replace the parts on the machine at will.

- To check the use of hydraulic oil in a timely manner to prevent downtime when working.

- Check the machine after use and make various records after confirming that it is correct.

Working video of the metal chip briquetting machine

The metal powder briquette machine is also suitable for pressing coconut husk powder. The following is the video of squeezing coconut husk powder, producing 4 bricks each time.

Coconut fiber powder briquetting machine, making 1 hollow brick each time.

Technical parameters of the metal powder press machine

| Model | Capacity | Density | Control system |

| SL-315T | 300-500kg/h | 2400kg/m³ | PLC automatic control |

Sucessful case: metal chips briquetting machine exported to Italy

This Italian customer has a steel factory, which produces a lot of steel bars every day and a lot of scrap. Therefore, according to his factory situation, he decided to purchase a machine to generate income again for these scrap.

After browsing to our website he found it very suitable, so he contacted us. Our sales manager recommended this metal briquetting machine to him according to his needs. After checking the information about the machine, such as machine configuration, machine parameters, machine working video, etc., the Italian customer was very satisfied and signed the contract with us immediately. After the machine was ready, we immediately arranged the transportation to the customer’s destination. After receiving the machine, the customer was very satisfied. He also said, if there is an opportunity, we can cooperate again.