Industrial Scrap Metal Shredder for Metal Recycling

Metal Crusher | Industrial Metal Shredder

Machine brand: Shuliy

Model: SL-400, SL-600, SL-800, SL-1000, SL-1200, etc.

Equipped motor: every shredder has two electric motors and two reducers.

Advantages: all purpose functions, wide applications and various models.

Service: customizations, after-sales services, etc.

Shuliy scrap metal shredder, also called twin-shaft shredder, crushes various waste metals like steel, iron, aluminum, etc. into small pieces for recycling. This industrial metal shredder is multi-functional equipment, suitable for wastes with different hardness, shapes, and sizes.

The final materials are in small pieces, which are space-saving, convenient for transportation, and recycling.

This metal shredder machine has the characteristics of high crushing efficiency, low noise, low energy consumption, and high output. It embodies the advantages of low speed and high torque shear design.

With the upsurge in the waste recycling industry, the double-shaft metal crusher has been more and more used in various recycling industries. If you’re interested, welcome to contact us!

Highlights of industrial metal shredder

- Wide range of applications. The metal scrap shredder can be used to tear up scrap steel and scrap iron, scrap aluminum, aluminum profiles, etc.

- Also, it can crush circuit boards, engine oil filter elements, electric devices, leather, wood, plastics, bones, and other materials.

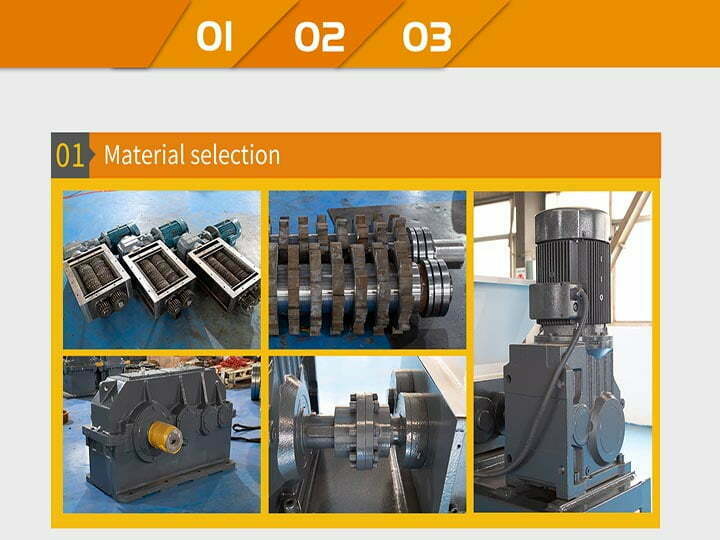

- Blade made of 9CrSi. 9CrSi is specially used for blades for metal crushing. This blade has strong shredding and high crushing capacity.

- Low-speed gear reducer. Due to this reducer, Shuliy scrap metal shredder has high transmission efficiency, stable operation, and low noise.

- Large torque. This metal crusher machine is suitable for materials of various volumes, especially waste materials with large volumes and irregular shapes.

- Easy operation. Equipped with a separate power control cabinet, you only need to operate the power control cabinet.

- Customization. Depending on different needs, we can equip the machine with the frame, working platform, conveyor(for feeding or discharging), etc.

Technical parameters of scrap metal crusher for sale

There are the main technical data of our metal scrap shredder models. Various models are available for your reference.

| Model | SL-400 | SL-600 | SL-800 | SL-1000 | SL-1200 | SL-1600 | SL-1800 | SL-2000 |

| Blade plate materials | 9CrSi | 9CrSi | 9CrSi alloy steel | 9CrSi | 9CrSi | 9CrSi | 9CrSi | 9CrSi |

| Blade plate dia.(mm) | 200 | 245 | 300 | 400 | 400 | 450 | 500 | 550 |

| Blade plate thickness(mm) | 20 | 20 | 40-50 | 30 | 30 | 40 | 50 | 100 |

| No. of blade(pcs) | 12 | 15 | 18 | 18 | 15 | 15 | 15 | 15 |

| Blade plate quantity(pcs) | 20 | 25 | 40 | 33 | 40 | 40 | 36 | 20 |

| Size(m) | 2.5*1.5*1.9 | 3.5*1.5*1.9 | 3.8*1.5*1.9 | 4.3*1.6*1.8 | 4.5*1.6*1.8 | 5.2*1.8*1.9 | 5.5*1.9*2.1 | 5.7*2*2.1 |

| Weight(t) | 1 | 3 | 4 | 6 | 7 | 12 | 16 | 22 |

| Power(kw) | 11 | 15*2 pcs | 18.5*2 pcs | 30*2 pcs | 37*2 pcs | 45*2 pcs | 55*2 pcs | 75*2 pcs |

Notes to mini scrap metal shredder:

- All motors are pure copper national standard motors.

- Reducers adopt the national standard weighted type.

Structure of mini scrap metal shredder

The main structure of the scrap metal shredder machine includes the feed hopper, frame, gear motor, electric motor, ladder, protective fence, pulley, protective cover, and discharge port. The following is the specific information.

- The size of the feed hopper is 60mm*60mm.

- The hopper size can be customized based on specific needs.

- Two motors are equipped with two gear reducers, ensuring stable work and avoiding noise.

- The protective cover on the pulley can play the role of dust prevention and safety protection.

- The guard rails and ladder are convenient for personnel to view and ensure safety.

- Shuliy metal crusher blades are made of high-strength and wear-resistant material.

- We offer blades with different hardness for selection to meet different demands.

- The blades adopt multiple claws and other structures to ensure that the claws can firmly lock the waste materials when tearing them.

Working principle of metal crusher

The working principle of the metal shredder mainly relies on its internal dual-axis shear system to complete the shredding process of metal waste. The following is its specific working principle:

- Feeding: first, the metal scrap to be processed is fed into the shredder through the feeding port.

- The feeding can be done manually or through an automatic conveying system.

- Double shaft shear: the core component of the scrap metal shredder is two rotating knife shafts arranged in parallel.

- Each shaft is equipped with multiple sets of high-strength alloy blades, which are arranged in a certain order and angle.

- When the shredder is started, these two knife shafts will rotate in opposite directions.

- Shearing and shredding: when the metal scrap is fed between the knife shafts, the rotating blades will generate strong shearing and tearing forces on the scrap, tearing it into smaller pieces.

- Since the rotating direction of the knife shafts is relative, it can effectively tear the metal scrap in multiple angles and directions.

- Discharge: the shredded metal fragments are discharged through the discharge port at the bottom of the shredder.

- If necessary, the discharging port can be connected to a conveyor belt or other transportation device to transport the fragments to a designated location.

Applicatable scrap of industrial scrap metal shredder

Our industrial metal shredder can be used to tear various scraps. We list the following raw materials for your reference.

- Ferrous metals

- Sheet metal: including thin gauge steel sheets and tin roofing and sidings, etc.

- Stampings: scrap produced in various stamping production.

- Chips: chips generated during metal processing.

- Molded parts: various molded metal parts.

- Home appliances: waste household appliances.

- Automobile panels: including automobile panels but not whole car shells.

- Aluminum alloy: various waste aluminum alloy products.

- Packed UBC: packed waste aluminum cans.

- Non-ferrous metals

- Copper: various waste copper products.

- Brass: including waste brass parts and copper anodes.

- Aluminum sheets and extrusions: waste aluminum sheets and extrusions.

- Copper pipes: waste copper pipes.

- Radiators: waste radiators.

- Silver-coated wires and plates: silver-coated wires and plates.

- Aluminum wheels: scrap aluminum wheels.

- Aluminum coils and coils: scrap aluminum coils and coils.

- Rubber and plastic

- Rubber tires: waste automobile tires, like car tires, truck tires, etc.

- Plastic: various discarded plastic bottles, plastic pipes, plastic films, etc.

- Wood and cardboard

- Wood: various kinds of discarded wood, like wooden pallets.

- Cardboard: waste cardboard, corrugated cardboard, etc.

- Household and textiles

- Waste furniture: including discarded wood and metal furniture.

- Large textiles: such as discarded fabrics and textiles.

- Electronics and appliances

- Electrical parts: discarded electrical parts and equipment, waste cables, etc.

- Electronic scrap: waste electronic circuit boards.

- Oil drums and cans

- Other materials that are difficult to handle

- Large animals: such as dead large livestock.

- Large pipes: scrap metal or plastic pipes.

How about the scrap metal shredder machine price?

The scrap metal crusher machine price is affected by several factors, such as machine models, capacity, the model of the speed reduction motor, and the motor.

If you want to know the exact price of a twin-shaft shredder, please contact us! Tell us your needs, we will provide you with the most suitable solution for your needs.

Why choose Shuliy as scrap metal shredder machine supplier?

We are very well known in the scrap metal recycling industry because of the following advantages.

- Technical support

- Pre-sale consultations

- On-site installation and operation training

- After-sales service

- Repair and maintenance services within the warranty period

- Wearing parts replacement services

- Long-term maintenance support and technical upgrading services beyond the warranty period

- Customized service

- Design and produce customized models according to your special requirements

- Spare parts supply

- Timely supply of original spare parts of small scrap metal shredder

Other metal recycling equipment: metal shears

We also have the hydraulic metal cutting machine available for metal recycling, like alligator shear, gantry shear, etc., with specific reference to the following:

Get in touch with us now for your scrap metal recycling!

Know how to do scrap metal recycling quickly? Come and contact us, our metal crusher will provide you with the optimal choice.