Hydraulic Metal Shear Machine | Alligator Shear

| Model | SL-1200 |

| Standard shear force | 250T |

| Motor | 4-22kw |

| Voltage | 380v/50Hz |

| Oil pump | 80*1 |

| Cutting blade length | 1200mm |

| Way to control | automatic/manual operation |

| Number of cutting per minute | 8-12 |

You can now ask our project managers for technical details

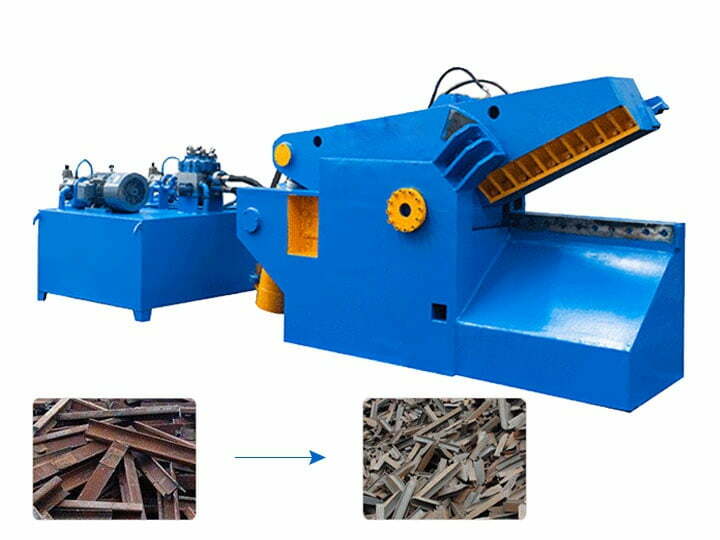

Shuliy hydraulic metal shear machine is mainly used for cutting various waste metal sheets, waste steel tubes, scrap steel plates, etc. into pieces for recycling. It can shear waste 8-12 times per minute.

This alligator shear can equip the conveyor for waste metal feeding. It has manual and automatic control types. When using this metal scrap cutting machine to cut scrap metal, the cutting length can be adjusted freely.

It is mainly used in the waste materials recycling and processing industry, and small and medium-sized steel mills. If you’re looking for a waste metal solution, this machine is the ideal choice.

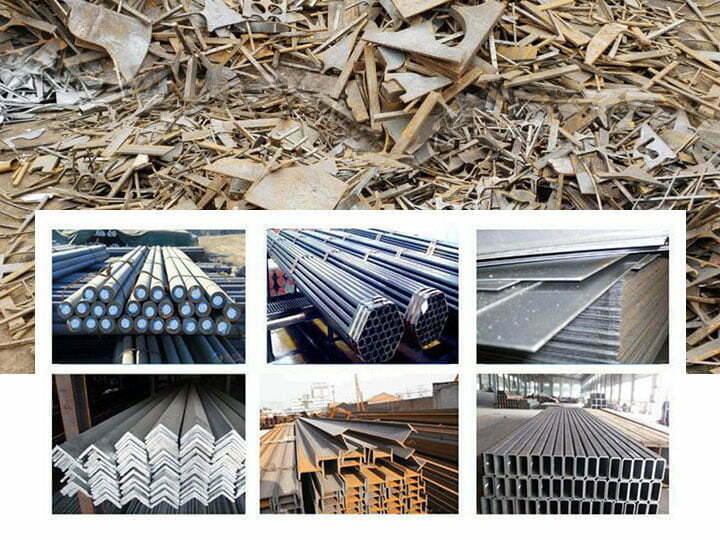

What metal waste can be cut?

This jaw type of scrap metal cutting machine is suitable for various metal waste cutting, such as:

Channel steel, waste iron, square steel, waste construction steel, rebar, angle steel, I-beam, steel pipe, iron sheets, cast iron, steel plates, colored steel tiles, metal scraps, aluminum alloy plates, copper plates, scrap metal plates, aluminum cans, scrap steel bars, aluminum plates, iron plates, round steel, scrap car shells, aluminum tanks, gasoline tanks, paint tanks, natural gas tanks, and so on.

Applications of hydraulic alligator shear

After learning what scrap metal cutting can be done, now it’s time to see where this equipment can be used.

This hydraulic metal shear machine is mainly used in:

- Steel mills

- Waste steel processing companies

- Metal waste recycling processing plants

- Scrap automobile dismantling plants

- Steel smelting and casting industries

Features of hydraulic metal shear machine

- Cutting blade lengths in 400mm, 600mm, 700mm, 800mm, 1000mm and 1200mm. This alligator shear has various cutting blade specifications, providing customers with more choices.

- The hydraulic metal shear machine with a cutting blade length of more than 700mm is particularly suitable for cutting scrapped automobiles.

- Few limitations for the raw materials for cutting. The shearing method is not strict with the feeding size of the waste metal materials. Thus, there are fewer restrictions.

- Shear force from 63 tons to 400 tons in 8 grades. Shuliy crocodile-type shearing machine has various types available, which is a wide range of choices for customers.

- Multiple power system choices. This machine can use an electric motor or diesel engine as the power system. Where there is no power supply, the diesel engine can be used as power.

Parameters of the hydraulic metal shearing machine

| Model | SL-1200 |

| Standard shear force | 250t |

| Motor | 4-22kw |

| Voltage | 380V/50Hz |

| Oil pump | 80*1 |

| Cutting blade length | 1200mm |

| Way to control | Automatic/manual operation |

| Number of cutting per minute | 8-12times |

This SL-1200 hydraulic metal shear machine has a strong shearing capacity, suitable for all kinds of scrap metal materials shear processing.

We can customize the voltage, blade length, pressure, etc. Shuliy can design these to meet your demands.

If you’re interested in metal waste recycling, welcome to contact us for more details!

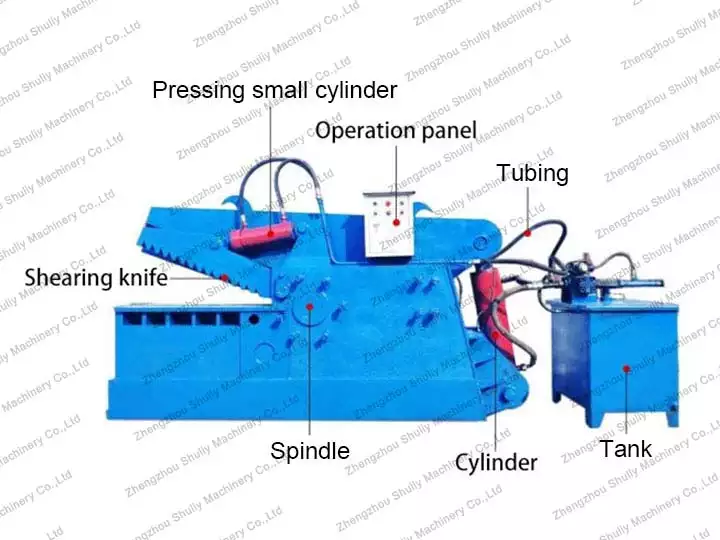

Structure of scrap metal cutting machine

The structure of the hydraulic metal shear machine mainly includes the frame, shearing head, pressing claw, shearing head action cylinder, pressing claw action cylinder, and hydraulic oil supply device.

From its design, it’s clear that this hydraulic metal shear has the convenient and simple operation.

The shear mouth can cut and stop at any position during the working process. According to the size of the material, arbitrarially control of the size of the shear mouth. This can achieve high working efficiency.

Working principle of crocodile-type alligator shear

This machine works through a hydraulic system.

When shearing is in progress, the hydraulic pump station (power output source) supplies oil to the pressing cylinder to push the slider pressing knife onto the lower knife seat. The material is fixed and compacted.

Then the hydraulic pump station supplies oil to the shearing cylinder to make the shearing knife move downward to complete the shearing step.

After shearing is completed, the hydraulic pump station completes the return stroke driven by the hydraulic oil reflux of the shearing cylinder and the pressing cylinder.

How about hydraulic metal shear price?

Shuliy hydraulic metal shear price varies depending on a variety of factors, including the model of the equipment, shear force, configuration, brand and after-sales service.

- Generally speaking, the larger the shear force, the higher the configuration of the hydraulic shear, its price is correspondingly higher.

- When buying hydraulic metal shears, in addition to focusing on the price, you also need to consider the quality and performance of the equipment.

- Choosing a brand with a good reputation and after-sales service guarantee, such as Shuliy, can ensure that the equipment is more reliable and efficient in the process of use.

If you need to know the specific hydraulic metal shear price, you can get a detailed quote by contacting our sales team. We will recommend a suitable model and provide the best price plan according to your specific needs.

Safe operation guides for hydraulic metal shear machine

- The metal cutting equipment shall be operated by specific personnel.

- Before using this alligator shear, carefully check whether all parts of the machine are normal and whether the fasteners are firm.

- The metal cutting machine is prohibited to cut:

- Non-annealed steel parts, cast iron parts, soft metal parts, thin metal materials, materials with lengths less than 100 mm, and metal waste exceeding the length of scissors.

- During the operation, the human body is not allowed to approach the transmission part and knife-edge of the equipment.

- The safety of the surrounding personnel shall be paid attention to prevent the material from warping and hurting people.

- When cutting, try to cut the material close to the inside of the knife.

- When cutting short materials, it is not allowed to use hand-held workpieces to feed materials. You can feed materials with a clamp.

- When the equipment is running, the operator shall not leave the post without permission.

- When the work is completed or temporarily left, the power supply shall be cut off.

- At the same time, when the machine is running, it is not allowed to repair or touch the moving parts with hands. It is strictly prohibited to press the materials in the material box with hands or feet.

- The lubricating parts of the machine shall be filled with lubricating oil at least once per shift as required.

New-type small hydraulic alligator shear machine

This new type of hydraulic metal shear machine is newly designed by our factory. This scrap metal shear is suitable for materials that cannot be cut too thick, such as plastics.

small metal shearing machine

The small crocodile-type shear machine has the advantages of cost-effectiveness, lightweight, easy movement and a small footprint. It’s ideal for small or start-up enterprises.

Contact us for more machine details!

As a professional metal equipment recycling manufacturer, we also have tiger-head metal shear, gantry shearing machine and so on, which can meet your different needs.

If you are looking for efficient solutions for metal waste recycling, contact us now. Our sales team will provide you with the best solution according to your needs.