Hydraulic Vertical Baler for Various Waste Recycling Press

| Model | SL-HZ-15T |

| Pressure | 15T |

| Motor | 5.5KW |

| The volume of the inner box | 850*600*1300MM |

| Final product size | 890*610*500MM |

| Capacity | 1-1.5T/H |

| Weight | 1T |

You can now ask our project managers for technical details

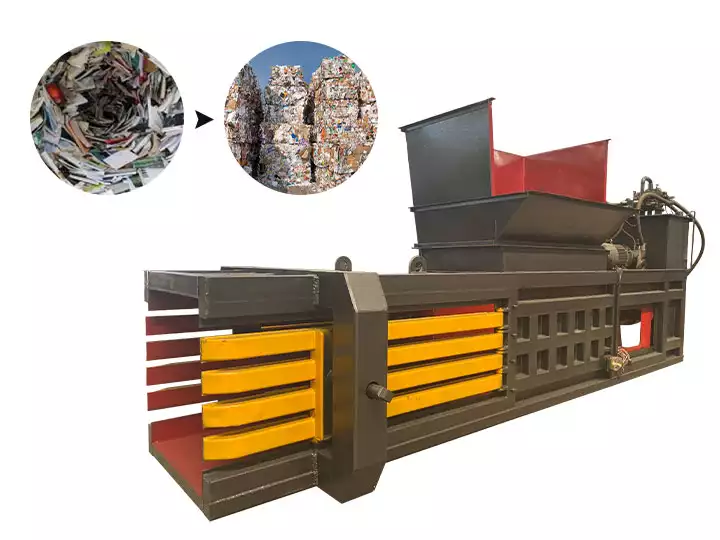

This vertical baler is designed for baling and compressing various cartons, plastics, and other materials. The machine is well designed and the bins can be designed to fit the finished product to the customer’s needs. In addition, it is a very practical machine that can be used in a wide range of applications, such as recycling plants, farmers, etc. Besides, our recycle baler is exported to Italy, Iraq, Indonesia, Malaysia, Algeria, Uzbekistan, etc.

Shuliy Machinery is very mature in the technology of manufacturing recycled machinery and can fully consider the interests of customers. Our company also supplies the scrap metal baler and horizontal baler.

What is a vertical baler?

A vertical baler is an equipment that compresses and packs waste plastic bags, plastic bottles, waste cardboard, and other materials. Its package is compact, neat, and beautiful, which can greatly reduce transportation costs. The materials processed by the recycling baler machine have the characteristics of high density and easy storage and transportation into regular shapes. It is especially suitable for large retail stores, cotton-producing areas, textile companies, hotels, garment factories, waste recycling stations, and various other light industrial enterprises.

Application scope of hydraulic vertical baler

There are innumerable packages that are unpacked every day in major commercial areas, and they vary in size and take up a lot of space. If they are not handled properly, they will increase the cost of garbage disposal and consume a lot of manpower and space.

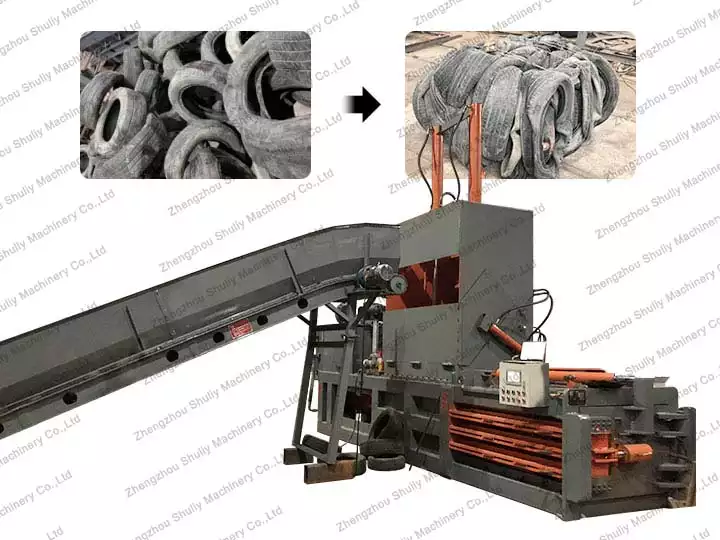

The vertical baling press machine is a method of compressing recyclable materials into regular shapes such as cuboids, cubes, etc. by means of a hydraulic system. The hydraulic compactor is suitable for compressing and packing waste paper, cotton, used clothing, straw, hay, plastic bottles, wool, and recyclable garbage. It can also be used for waste cartons, waste cardboard, waste paperboard, tires, yarn, tobacco, cloth, woven bag, knitted velvet, wool ball, and all other loose materials.

After pressing, users can bundle the materials with iron wire or plastic tape and take them out for storage, transportation, and recycling.

What industries are suitable to buy this vertical baler?

This baler is mainly used in industries that may produce large quantities of waste paper, plastic, cardboard, aluminum cans, cotton, etc.

Such as the packaging industry, carton industry, printing industry, paper industry, food industry, garbage collection industry, smelters, farms, clothes recycling organizations, waste recycling plants, cardboard production centers, supermarkets, department stores, grocery stores and printers, secondary recycling organizations.

Because for them, it will mean less waste storage area, simplify overall waste handling operations and save on transportation and labor costs.

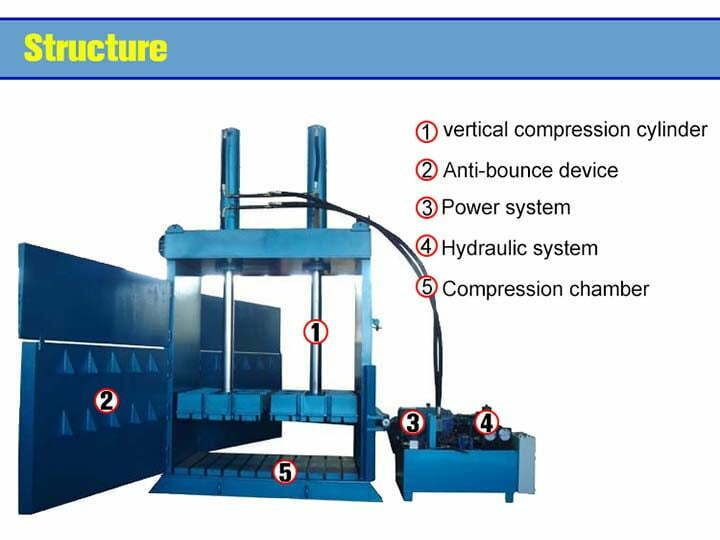

Structure of the heavy-duty vertical baler

The scrap baling press is mainly composed of hydraulic cylinder, motor and oil tank, pressure plate, box and base, upper door, lower door, door latch, strap support, iron support, etc.

The role of the hydraulic system is to increase the force by changing the pressure. A complete hydraulic system consists of five parts, namely power components, executive components, control components, auxiliary components and hydraulic oil. Hydraulic systems can be divided into two categories: hydraulic drive systems and hydraulic control systems. The main function of the hydraulic transmission system is to transmit power and movement. Generally speaking, the hydraulic system mainly refers to the hydraulic transmission system.

Hydro-mechanical transmission power is large, and it is transmitted by fine pipes and flexible hoses, so its power density is high. In addition, the power-applicable actuator is wide and flexible, and the pressure area is changed appropriately to increase the force.

Advantages of vertical baler machine for sale

- High pressure and compaction ratio. The compaction ratio can reach 5:1.

- A large driving force, suitable for heavy load direct drive;

- High precision and fast response;

- Small footprint and light weight;

- Wide range of speed regulation and various speed control methods;

- Anti-rebound barb to maintain the compression effect.

- The pressure plate returns automatically.

Specification of the vertical bale press

| Model | Pressure | Motor | The volume of the inner box | Final product size | Capacity | Weight |

| SL-HZ-15T | 15T | 5.5KW | 850*600*1300MM | 890*610*500MM | 1-1.5T/H | 1T |

| SL-HZ-30T | 30T | 7.5KW | 800*400*1300MM | 890*610*500MM | 1.5-2T/H | 1.5T |

| SL-HZ-60T | 60T | 7.5KW | 900*600*1300MM | 900*610*500MM | 2-2.5T/H | 2T |

| SL-HZ-80T | 80T | 7.5KW | 1200*800*1500MM | 1200*810*500MM | 3-3.5T/H | 3T |

| SL-HZ-100T | 100T | 15KW | 1100*900*1500MM | 1100*910*500MM | 3.5-4T/H | 3.5T |

| SL-HZ-120T | 120T | 18.5KW | 1200*100*1500MM | 1200*100*500MM | 4-5T/H | 4T |

How much does a vertical baler cost?

- Output. Because the machine has a lot of output, when you want more output, certainly the machine is to be more expensive.

- Machine configuration. Our machine‘s hydraulic rod has a single and double configuration, the price is certainly different.

- Customization. If you want to customize a machine, the price of the machine is definitely different compared to the conventional.

How to make money with industrial baler?

The industrial baler has a vertical baler and a horizontal baler. It is divided into a full-automatic baler and a semi-automatic baler. It is used to compress waste and recycled items. After being processed by the hydraulic baler, the space occupied by the waste material is directly reduced by 80%, and at the same time, the number of transportation and the cost is reduced. Customers who want to invest in a baler can first invest in a vertical baling press machine, which has a small footprint and is very suitable for use in small spaces.

Company advantages of buying this hydraulic baler machine

- Shuliy Machinery has a high-quality, young, and innovative research team. Our team will design the most suitable products according to the market demand of customers.

- Our balers have a high market coverage, not only popular in China, but also exported to Europe, Southeast Asia, America, and other countries and regions.

- We have a professional sales team and also provide after-sales service. Professional knowledge is essential, and after the machine is sold, our personnel will also provide our customers with attentive 24-hour service, just in case they need it.

How to pack the vertical baling machine?

During the transportation of the hydraulic scrap baling press (usually by sea), it may bump into the weather such as high wind and waves.

Therefore, in order to protect the safety of our customers’ goods, we will provide professional, environmentally friendly, convenient, and efficient packaging services.

The machines will be packed with wooden boxes and stands, which are both moisture-proof and collision-proof.

What are the services provided?

- One-year warranty and lifetime maintenance.

- Spare parts: one set of spare parts, toolbox, and operation manual will be provided free of charge.

- If any problem, you can call us directly.

- About the after-sales service, you can contact us at any time if you have any after-sales problems.

Conclusion

The vertical baler produced by our company has complete specifications, and the packaging volume of the product can be adjusted. The products we produce are strictly tested and reasonably priced. If you are interested in our vertical baling press machine, you can get free consulting services. You can contact us in time to provide preferential prices.

The vertical balers we produce are space-saving, easy to use, durable, and meet the needs of many customers. We have many years of experience in the production of recycling equipment and attach great importance to customer requirements. We also provide guaranteed after-sales maintenance, technical training, and detailed product operation instructions. We hope to cooperate with you and hope to receive a reply as soon as possible.