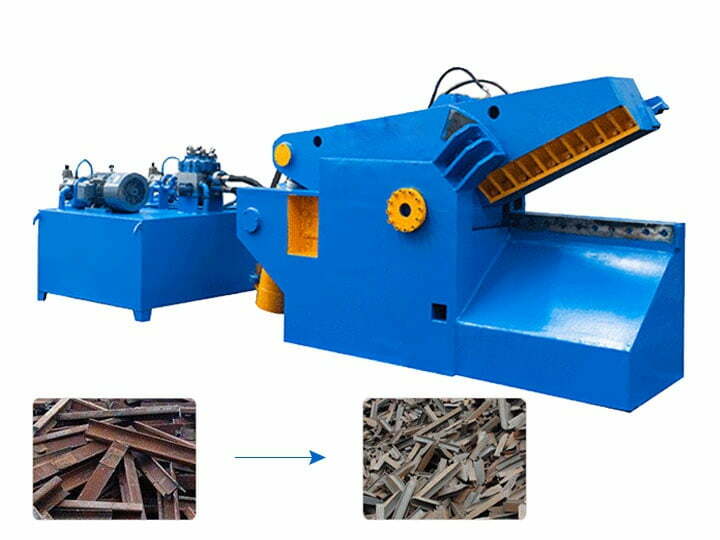

Metal Shear Machine for Scrap Cutting

| Brand | Shuliy |

| Capacity | 5-8times per minute(adjustable) |

| Raw materials | Round steel, square steel, channel steel, angle steel, beam, plate, steel pipe, steel plate, I-beam, etc. |

| Matched device | Chain plate conveyor |

| Advantages | High efficiency, powerful shearing applications, easy operation, etc. |

You can now ask our project managers for technical details

Shuliy metal shear machine, also known as a “tiger-head shearing machine”, is to cut scrap metal like light steel materials, copper tubes, iron sheets, etc. into the required sizes. It can cut metal waste 5-8 times per minute, which is adjustable.

Our hydraulic metal cutting machine has working widths of 1m and 1.2m(the blade opening size). We can also customize it to meet your demands.

This machine has two blades, one to press waste metal and another one to cut scrap. For convenient metal cutting, the chain feeder is optional.

Our hydraulic metal shearing machine is very popular because of its powerful shearing applications, safe and simple operation, continuous cutting, and high production efficiency.

If you’re looking for a solution for scrap like steel tubes, this metal cutting shear is your ideal choice.

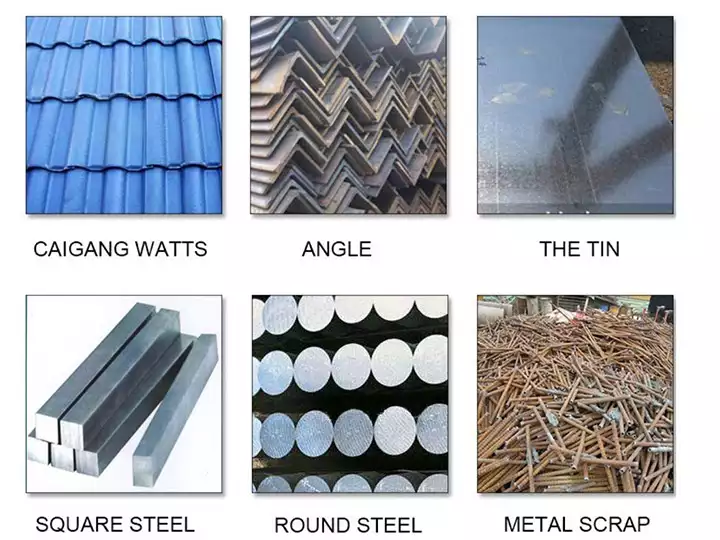

Scrap metal to be cut & applications of metal shearing machine

Our metal shear machine can cut various metal scraps, such as:

Round steel, square steel, channel steel, angle steel, beam, plate, steel pipe, steel plate, I-beam, aluminum lumps, iron plates, copper tubes, etc.

After knowing which metal can be cut with the tiger-head hydraulic metal shear, what places or industries use it?

This kind of metal cutting machine is widely used in:

- Scrap metal recycling and processing stations

- Iron and steel mills

- Metallurgical industry

- Large-scale scrap recycling centers

Advantages of hydraulic metal shearing machine

- Cutting waste metal with a speed of 5-8 times per minute(adjustable). Our metal shear machine can cut waste metal 5-8 times within one minute, which is efficient. And you can adjust cutting times.

- Shearing steel plate, steel pipe, scrap iron, scrap steel, aluminum, etc. Shuliy sheet metal cutter machine is capable of shearing various metal materials. It has a wide range of applications.

- Continuous cutting with the chain feeder. For convenient and uninterrupted cutting, our shears can add the chain plate conveyor, more convenient and fast.

- Easy operation. The scrap metal shearing machine is reasonably designed. Workers can master the use of equipment after a short period of training.

Technical parameters of sheet metal shear machine

| Model | SL-250 | SL-300 |

| Max. shearing force | 2500KN | 2500KN |

| Shear cylinder stroke | 450mm | / |

| Max. press force | 2500KN | 2500KN |

| Press cylinder stroke | 450mm | / |

| Working table height | 800mm | 800mm |

| Capacity | 5-8times per minute(adjustable) | 5-8times per minute(adjustable) |

| Shear knife working length | 1000mm | 1000mm |

| Max. opening of the corresponding blade | 550mm | / |

| Hydraulic pump | 80YCY | / |

| Motor power | 22kw | 22kw |

| Dimension of main machine | 2000*1200*1800mm | 2000*1200*2100mm |

| Hydraulic station size | 1600*1200*1400mm | / |

The above parameters are for your reference when choosing a metal shear machine.

Please tell us your material type, thickness, etc., and our sales manager will recommend the right model for you.

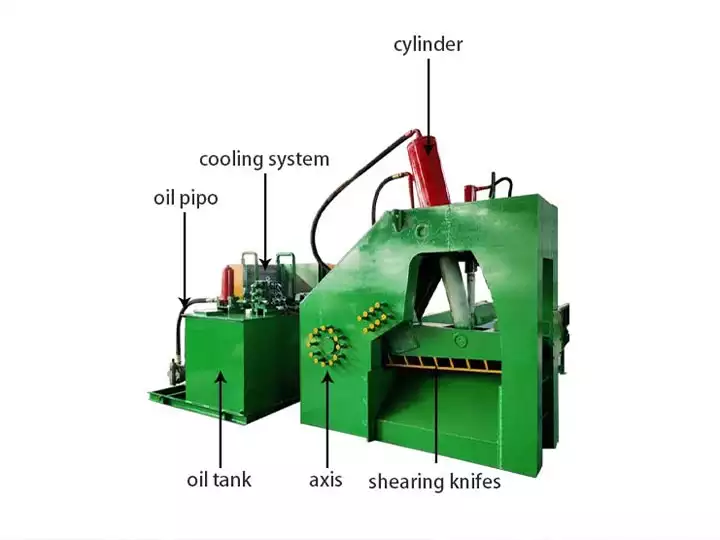

Structure of scrap shear machine

The scrap metal shear machine mainly contains the shearing oil cylinder, shearing knife, sliding block pressing knife, lower knife seat, pressing oil cylinder, etc.

The main unit and the hydraulic cylinder are separate, ensuring safety when in use.

Working principle of shear metal cutting machine

The working principle of the tiger-head metal shear machine is to use the hydraulic system to drive the cutter head.

Place the scrap metal material under the cutter head, and the cutter head is pressed down by the hydraulic power to complete the cutting operation.

The sheared metal block can be adjusted to the required size for easy storage and transportation.

Supportive equipment for metal shear cutter

The hydraulic metal shearing machine can be connected to a chainplate feeder for automatic feeding.

The chain plate feeder realizes smooth feeding, avoiding the material bulge of the traditional conveying mechanism.

Tips on choosing metal shear machine

When purchasing a metal shear, it is important to ensure that the equipment is capable of meeting the processing requirements.

In order to purchase an economical and practical hydraulic metal cutting machine, it is recommended to pay attention to the following points:

- Clarify the size and material of waste. This will help you to choose the appropriate tonnage of the machine to ensure shearing efficiency and effectiveness.

- Choose special blades for special materials. Special materials or wastes have great hardness. So, you need special blades to reduce the trouble of replacement.

- Select equipment that is easy to install and operate. The integrated design of the equipment does not require complicated installation, is easy to operate, and helps improve work efficiency.

Contact us now for more details!

If you are looking for a solution for scrap metal shearing, contact us!

In addition to this shear, we also have the alligator shear and gantry shear machine. No matter what type of scrap, we can handle it.