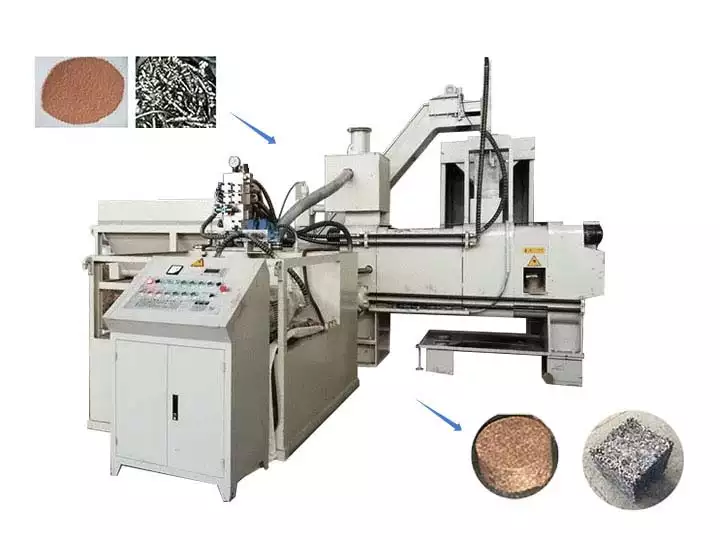

Horizontal Metal Chips Briquetting Machine

| Model | SL-2000 |

| Briquette diameter | 60~90mm |

| Speed | 2~3briquettes/min |

| Motor | 18.5kW |

| Briquette density | Aluminum≤2.5ton/m³ |

| Model | SL-2500 |

| Briquette diameter | 90~110mm |

| Speed | 3~5briquettes/min |

| Motor | 18.5kW |

| Briquette density | Aluminum≤2.5ton/m³ |

You can now ask our project managers for technical details

The horizontal type of metal chips briquetting machine is the commercial scrap metal press equipment, which can be widely used in various metal briquettes production lines. The common metal shavings like aluminum chips, iron powder, copper shavings and chips and other kinds of metal scraps can be pressed into briquettes with high density for easy transporting.

Brief introduction of the automatic metal chips briquetting machine

The copper shavings cake briquette machine is designed in a horizontal structure. It can squeeze various kinds of metal scraps horizontally. It can compress granular and powdery metal shavings into 2-8kg cylindrical cakes. With high working efficiency for recycling scrap metal resources, this metal chip briquette machine can be widely used in steel casting plants, metal smelters, construction industry, environmental pollution prevention enterprises, and machinery processing plants.

What are the components of the metal chips briquetting machine?

The metal chip briquetter is mainly composed of a compression oil cylinder, a compression chamber, a hydraulic system, an electrical system, a safety control system, and an automatic bag-out system. The machine can be equipped with a diesel generator drive, suitable for areas with poor power supply.

How to design the metal chips briquetting machine?

A three-beam, six-post structure

The metal chips briquette machine uses this type of structure.

The upper beam and workbench of the briquetting machine are combined into a fixed frame through columns, fastening nuts, and adjusting nuts.

The accuracy of the frame is adjusted by the adjusting nut, which has good strength, rigidity, and accuracy retention.

Welded steel plates

The upper beam, table, slider, and other large pieces use this plant. These parts are optimized and designed by the computer. Its strength, rigidity, structure, and deformation resistance meet the international standards and use requirements, and ample safety factor. The powder metal press uses carbon dioxide gas shielded welding and manual arc welding so that its welding quality is very high and can eliminate deformation stress through aging vibration treatment.

The slider of the briquetting machine

Actually, it’s a welded steel plate with a box structure. The material of the guide sleeve at its four-column guide hole is a nano-molecular composite material, which has good resistance and precision retention.

On the lower plane of the slider, there are T-slots for mold installation.

The main beam has a main working oil cylinder. On the main working cylinder, there is a liquid-filled oil tank. The workbench of the metal chips briquetting machine is also a steel plate welded structural part, which is connected with the upper beam and the slider through a column to form a host.

The design of the copper cylinder

The copper cylinder of the briquette machine uses a five-cylinder design, which is arranged in the upper beam hole and sealed with a double-channel seal. The guide part is treated with copper welding, which is sealed and has good wear resistance. The material of the cylinder body is 45 forged steel. , Forgings are grade 3 (forgings are qualified by ultrasonic flaw detection, and quenched and tempered).

How does the hydraulic aluminum chip briquetter work?

This metal chips briquetting machine uses hydraulic pressure provided by hydraulic cylinders to compress materials.

During work, the rotation of the motor can drive the oil pump to work, extract the hydraulic oil in the oil tank, transport it through the hydraulic oil pipe, and transfer it to each hydraulic oil cylinder to drive the piston rod of the oil cylinder to longitudinally compress various metal chips in the material tank.

Maintenance tips of the horizontal metal briquetting machine

- It is recommended to use 32 and 46 anti-wear hydraulic oil for the hydraulic oil used when the machine is working. Use oil temperature in the range of 15 to 60℃.

- The hydraulic oil is strictly filtered before being allowed to be added to the tank. The working fluid should be changed once a year, and the replacement time should not exceed three months.

- If the machine is not used for a long time, the surface of each part should be cleaned and coated with anti-rust oil.

- The slide of the metal briquette machine should be filled with lubricating oil frequently, the outer surface of the column should be kept clean frequently, and the oil should be injected before each work. The pressure gauge should be checked every six months.

Technical specifications of the metal briquette press

| Model | Briquette diameter (mm) | Speed (briquettes/min) | Motor (kW) | Briquette density (ton/m³) |

| SL-2000 | 60~90 | 2~3 | 18.5 | Aluminum≤2.5 |

| SL-2500 | 90~110 | 3~5 | 22 | Aluminum≤2.5 |

| SL-3150 | 100~110 | 3~5 | 30 | Steel, cast iron≤5.5 |

| SL-3600 | 100~130 | 3~5 | 30 | Steel, cast iron≤5.5 |

| SL-5000 | 120~160 | 3~5 | 22×2 | Brass, copper≤7.0 |

| SL-6300 | 120~200 | 3~5 | 30×2 | Brass, copper≤7.0 |