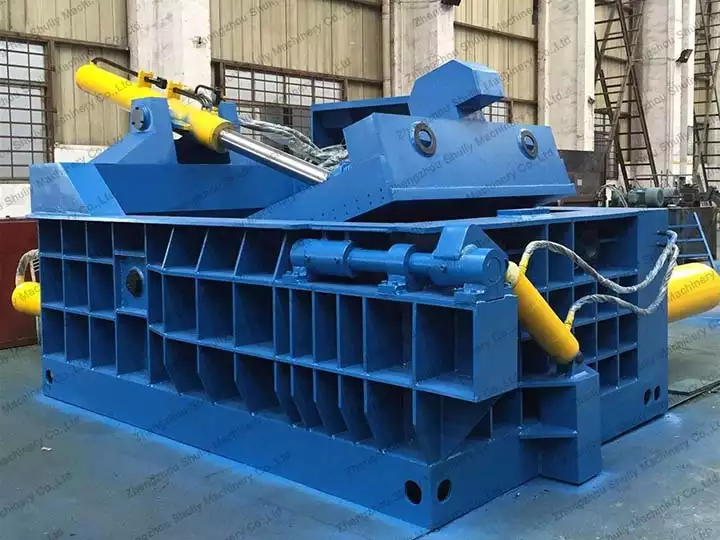

Hydraulic Scrap Metal Baler for Waste Baling Press

Metal Compactor | Metal Scrap Baling Press

Model: SL-Y81-125

Pressure: 125t

Press bin size: 1200*800*500mm

Bales size: 30*30cm

Press time: 10s

Power: 15kW

Features: Customization

Service: After-sales service, online guidance, etc

The horizontal scrap metal baler (also called waste iron baler, cans baling machine, waste steel baling machine, and aluminum cans baler) is mainly to compact waste metal like aluminum, iron, steel, etc. into density scrap metal bales for recycling and recreating profits.

This kind of metal compactor has very wide applications for pressing all kinds of metal wastes and other solid wastes with cylindrical, rectangular, cube, hexagonal, and other multi-prism shapes. Its hydraulic pressure can be adjusted according to the actual baling requirements of a certain kind of material.

Due to its high efficiency, customization high efficiency, customisability and less maintenance, our metal balers are very hot sellers in foreign countries, such as Malaysia, Kuwait, Philippines, Afghanistan and so on. If you want to do recycling, welcome to contact us at any time!

What is a scrap metal baler?

This scrap metal compactor can be widely used in medium-sized or large metal resources recycling plants and metal products manufacturing factories.

The hydraulic scrap baling press machine uses multi-strength from its hydraulic system to press metal wastes of irregular shapes and sizes into compact columns. After baling, these scrap metal bales are easy to transport and store in the bins as well as saving much land occupied.

What waste material can be baled by hydraulic scrap baling press?

The hydraulic scrap baling press is suitable for various large, medium, and small steel mills, the waste metal recycling processing industry, and the non-ferrous metal smelting industry.

The scrap metal baler can press various metal scraps, steel shavings, scrap steel, scrap aluminum, scrap copper, etc. into qualified shapes such as cubes, cylinders, octagons, etc. to reduce the transportation and smelting costs of metal scrap materials.

The scrap iron baler is a kind of mechanical equipment for extruding various waste metal products under normal conditions.

Various cans, paint buckets, tin cans, scrap iron, scrap steel, iron sheets, used bicycles, color steel tiles, light and thin iron sheets, pig iron blocks, cans, beer cans, scrap aluminum flakes, scrap copper blocks, iron barrels, car shells, automobile racks, and aluminum alloy materials can be pressed and formed at one time by using the hydraulic scrap metal baler, which can improve the speed of furnace operation and labor efficiency.

Advantages of the hydraulic scrap metal baler

- Great scrap metal baler design, space-saving, and more convenient transportation.

- The metal scrap after baling is denser and can be sold at a higher price

- Our metal scrap baling press can be used for scrap, which can generate income again for the factory.

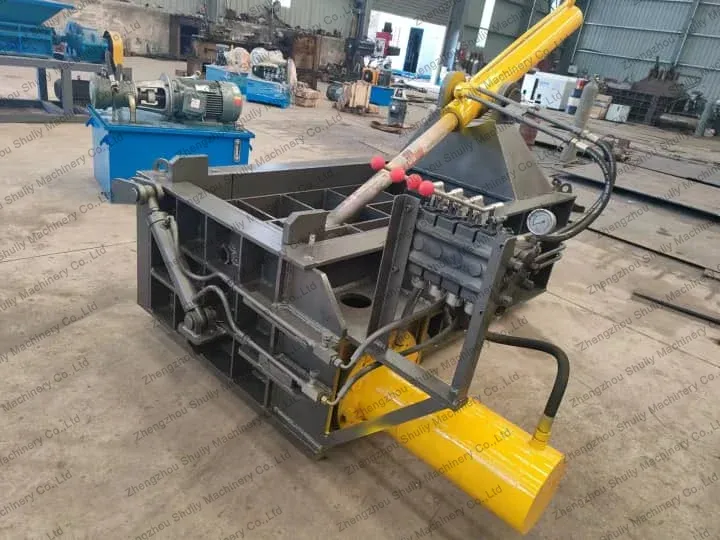

- There are two kinds of operating systems, one is fully automatic and the other is manual operation (operation is by hand control lever).

- The plate can be added to the machine based on the original so that the machine is more wear-resistant, longer service life.

- You can also add the blades, so more convenient to pack large materials.

How does the metal scrap baling press work?

Metal materials have the property of plastic deformation. The hydraulic pressure of the horizontal metal baler can give the metal materials sufficient external force that can aggregate and produce permanent deformation, thereby forming a compact solid block.

When the hydraulic scrap baling press is working, we can use the grab machine to place the materials to be packed into the box of the packer. Next, open the machine’s hydraulic cylinder control valve. The hydraulic metal baler itself has three hydraulic pressures accumulating on each other, which can quickly compress metal materials into columns.

Maintenance tips of the scrap metal baler

- Every week, clean the scraps or dirt in the bin of the metal baler.

- Once a month, clean and lubricate the slide, middle knife, and front ejector.

- Add lubricant to all bearings of the machine every three months.

- Regularly replenish the hydraulic oil in the oil tank of the metal baler once every two years.

- Every time you add hydraulic oil, it should be appropriate. Remember not to add too much, so as to avoid malfunction of the microswitch due to oil immersion.

Technical parameters of the scrap metal baler for sale

| Equipment model | Pressure(ton) | Press bin size(mm) | Bales size(cm) | Press time(s) | Power(kW) |

| SL-Y81-125 | 125 | 1200*800*500 | 30*30 | 100 | 15 |

| SL-Y81-135 | 135 | 1200*1000*600 | 30*30 | 110 | 18.5 |

| SL-Y81-160 | 160 | 1200*1000*600 | 35*35 | 110 | 18.5 |

| SL-Y81-180 | 180 | 1600*1200*800 | 40*40 | 130 | 22 |

| SL-Y81-200 | 200 | 1600*1200*800 | 50*50 | 140 | 22+15 |

| SL-Y81-250 | 250 | 2000*1750*1000 | 50*50 | 150 | 44 |

| SL-Y81-315 | 315 | 2500*2000*1200 | 60*60 | 160 | 60 |

| SL-Y81-400 | 100 | 3000*2500*1200 | 60*60 | 170 | 90 |

Successful cases of scrap metal balers for sale all over the world

Successful case: the horizontal metal baler exported to Iraq

The Iraqi customer had a large accumulation of metal scrap and wanted to dispose of this material efficiently, preferably in a way that would generate secondary income. Therefore, this customer started looking for a metal baler and contacted us after seeing our machines. After learning about our machines, he was very satisfied and felt that this was the machine he wanted. Therefore, the contract was signed immediately. Here is a picture of our delivery to the port.

SL-125 hydraulic scrap metal baler sold to Afghanistan

Our metal compactor was successfully sold to a large scrap metal recycling company in Afghanistan. Due to the excellent stability and durability, the company can be able to quickly process all kinds of scrap metal. The company has significantly improved the efficiency of scrap metal processing, reduced transport costs and increased the effectiveness of resource recovery.

SL-125 metal compactor delivered to Malaysia

In Malaysia, we provided a scrap metal baler solution for a company specializing in metal recycling. We customized the metal baler with 15 kW power and 30*30 cm bale size with the side push bale method for Malaysia.

Get in touch with us for a quote!

Interested in how fast you can do scrap metal recycling? If so, get in touch with us! We will provide you with the optimal solution and the best offer according to your needs.