Why is double-shaft industrial shredder so powerful & durable?

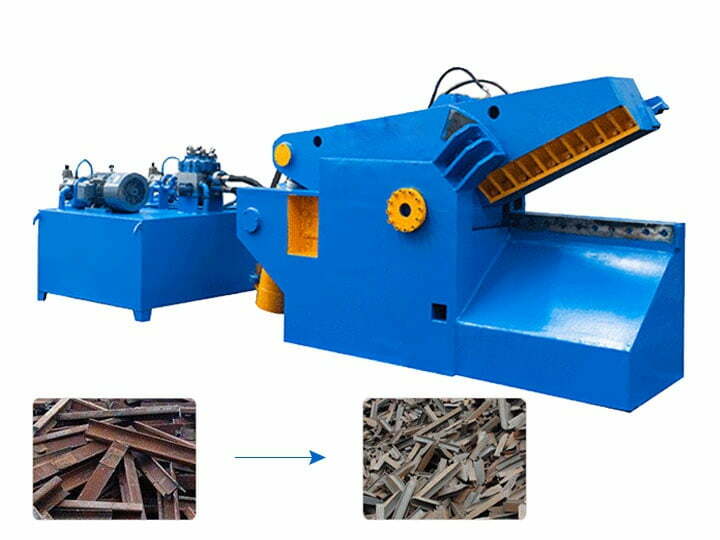

The double-shaft shredder industrial shredder, also known as a scrap metal shredder, is widely used in the recycling of scrap metal, waste plastics, waste rubber, wood, and other large-volume wastes. Featured with the advanced design of the double-shaft structure, high torque, unique blades, etc., the industrial shredder machine is able to tear up all kinds of waste materials for resource recycling, such as waste furniture, paint barrels, chemical barrels, scrap metals, wood products, tires, household appliances, plastic products, etc. Through the processing of the metal shear machine, the bulk density of materials can be greatly increased. The reduction of material volume is convenient for transportation and further processing.

Why is the industrial shredder machine so powerful?

The double-shaft industrial shredding machine is based on the principle of mutual rolling, shearing, and shredding of two blade-shafts. The shredder blades are in a multi-claw structure. During the rotation of the main shaft, the shredder machine cuts materials into strips and also cuts off the materials through the claw head structure of the claw to realize the shredding effect of materials. The double-shaft shredder equipment has the characteristics of low speed, high torque, and low noise, especially for materials with high hardness and large volume.

industrial crusher

double-shaft structure

Shredding blades with extremely strong durability

The blade is one of the important parts of a double shaft shredder machine. The quality of the shredder blade directly affects the crushing cycle of solid waste. The blade of the double shaft shredder is strong, wear-resistant, and repairable. The cutter of the industrial shredding machine is made of high-quality wear-resistant materials, which can crush objects with high hardness such as metal. The blade materials can be selected for different use, like 9CrSi, 55SiCr, and H13. All cutting blades adopt advanced heat treatment technology and high-precision machine tools, with long service life.

shredder machine blades

industrial shredder blades

double shaft

The blade can wear during normal use. When the blade is worn to a certain extent, it needs to be repaired or replaced in time. The double shaft shredding motorized blade is detachable and easy to replace. It has good wear resistance and can be repaired by surfacing at room temperature after wear.