Vertical Metal Baler | Hydraulic Baling Press

| Brand | Shuliy |

| Capacity | 6-10 bales per minute |

| Bale size | 800*400*800mm, 800*400*600mm, 1150*750*1000mm, etc. |

| Scrap to be baled | Steel, iron, aluminum, copper, lead, zinc, etc. |

| Advantages | High efficiency, cost-effectiveness, customization, etc. |

| Warranty period | 1-2 years |

You can now ask our project managers for technical details

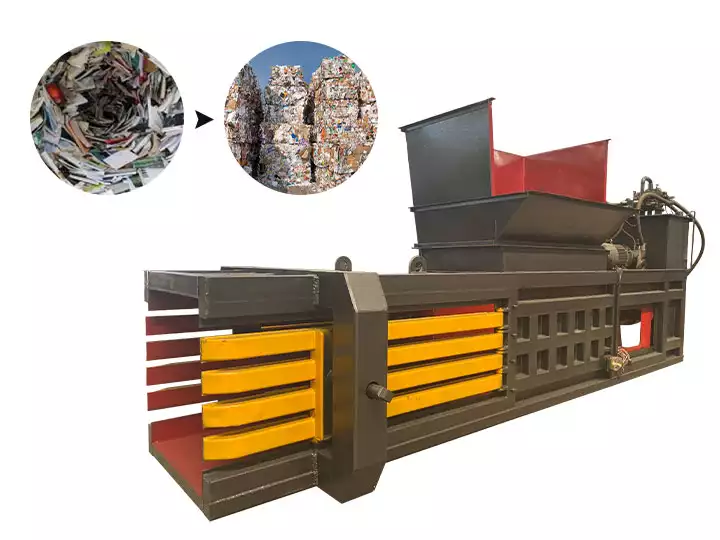

Shuliy vertical metal baler is to compress all kinds of metal wastes(such as scrap steel, scrap aluminum, scrap copper, etc.) into blocks through high pressure. After pressing, the baled metal bales are for easy storage, transportation and recycling.

The machine has a baling speed ranging from 6-10 bales per minute. It can press bales with sizes of 800*400*800mm, 800*400*600mm, 1150*750*1000mm, etc. We can customize the bale size to meet your demands.

This hydraulic baling press has the advantages of simple operation, wide applications, and cost-effectiveness.

Our vertical baler can also be used for baling cartons, cloth, plastic bottles, and so on. If you’re interested, please feel free to contact us.

Advantages of Shuliy hydraulic baling press

- Capacity of 6-10 bales per minute. Our baler uses a powerful hydraulic system to press the waste of 6-10 bales in one minute, which is efficient.

- Intelligent control panel & intuitive user interface. This design is user-friendly. Even if you’re a new person can get started quickly.

- Baling many kinds of metal materials. This vertical metal baler is suitable for many kinds of metal wastes such as scrap steel, scrap aluminum, scrap copper, etc.

- Cost-effectiveness. We’re factory direct sales. With upgraded technology, we can produce balers in batches, ensuring the quality while reducing the price, which is cost-effective.

- Low maintenance cost. The equipment structure is simple and easy to understand. Daily maintenance is very simple and inexpensive.

- Customizable compression force, compressed block size and others. According to your needs, we can customize these. Also, we can customize voltage, power, etc.

Technical parameters of the hydraulic vertical metal baler

| Model | SL-10T | SL-20T | SL-30T | SL-60T | SL-80T |

| Power | 5.5kW | 7.5kW | 11kW | 15kW | 17kW |

| Bale size | 800*400*800mm | 800*400*800mm | 800*400*600mm | 1150*750*1000mm | 1150*750*1000mm |

| Pressure | 10t | 20t | 30t | 60t | 80t |

| Dimension | 1400*700*2900mm | 1400*700*2950mm | 1450*800*2950mm | 1700*1000*3200mm | 1800*1000*3200mm |

| Oil cylinder | φ125 | φ160 | φ160 | φ160 | φ180 |

| Baling speed | 8-10bales/min | 8-10bales/min | 8-10bales/min | 6-10bales/min | 6-10bales/min |

| Weight | 400kg | 850kg | 950kg | 1600kg | 2000kg |

Our hydraulic baling press has various models for sale, respectively SL-10T, SL-20T, SL-30T, SL-60T, SL-80T, etc. If you’re interested, welcome to contact us for more details!

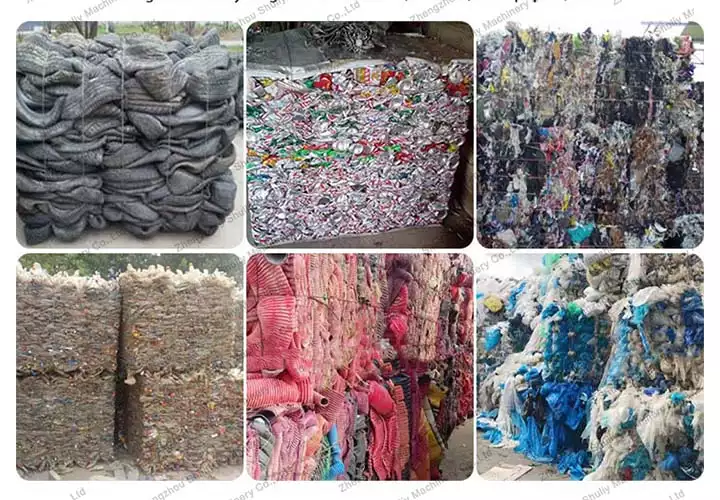

Metal waste and other scraps to be baled

Our vertical baler is multifunctional and suitable for all kinds of waste material pressing. Now, I will introduce the scrap materials that can be baled.

- Scrap steel

- Waste steel, steel plates, steel pipes, steel bars and other scrap materials in various forms.

- Aluminum scrap

- Scrap aluminum cans, aluminum plates, aluminum tubes, aluminum foil and other forms of aluminum materials.

- Copper scrap

- Waste copper wires, copper pipes, copper plates, copper chips, etc.

- Scrap iron

- Various forms of iron materials such as scrap iron, iron scrap, iron wire, iron plate, etc.

- Stainless steel scrap

- Waste stainless steel appliances, stainless steel plate, stainless steel pipe and other forms of stainless steel materials.

- Scrap lead

- Waste lead sheet, lead pipe, lead block and other forms of lead materials.

- Zinc scrap

- Zinc plate, zinc pipe, zinc block and other waste zinc materials.

- Alloy waste

- All kinds of waste metal alloy materials, such as copper alloy, aluminum alloy, nickel alloy and so on.

- Electronic scrap

- Metal parts in waste electronic products, such as wires, and circuit boards in the metal components.

- Others: waste rubber, clothes, waste cardboard, pipes, plastic bottles, cans, foam, sponge, etc.

Applications of Shuliy vertical baler machine

After knowing scrap materials to be bales, now let’s see its applications.

- Scrap metal recycling station

- Used to compress various metal scraps into blocks for easy transportation and reuse.

- Metal processing plant

- Compact metal scrap generated in the production process into blocks. This can reduce storage space and improve resource utilization.

- Scrap collection stations

- Compress various metal scraps purchased into blocks. This improves transportation efficiency and reduces costs.

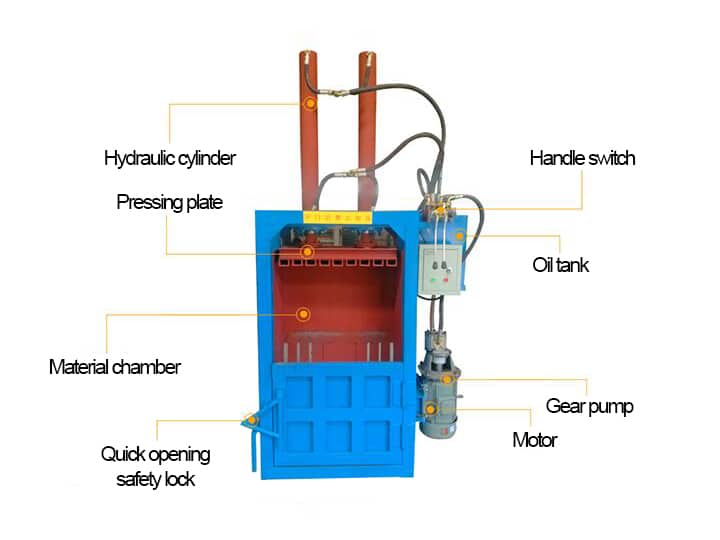

Structure of the hydraulic vertical baler

Its structure includes the hydraulic cylinder(double), material chamber, quick opening, hand switch, oil tank, gear pump, and motor.

Compared with the horizontal-type baler, this vertical baler is the smallest and most commonly used one. It’s usually used for small and medium-sized waste recycling plants. If you’re interested, welcome to contact us for more details!

Working process of the vertical baling machine

Loading

Put the metal scrap into the compression chamber of the vertical metal baler.

Compression

Activate the hydraulic system and the compression plate will move downwards to compress the metal scrap into blocks.

The strong hydraulic pressure ensures that the scrap is compressed to a minimum volume.

Strapping

Once compression is complete, the machine automatically/manually bundles the compressed blocks. This keeps them tight for easy handling and storage.

Discharging

After compression and strapping, the machine automatically pushes out the compressed metal blocks. Then the machine is ready for the next batch of scrap to be compressed.

Precautions for using the hydraulic metal baler machine

To correctly use this vertical metal baler machine, you should master the machine structure and operation procedures. Also, there are some points you should attention to.

- The high-quality anti-wear hydraulic oil should be strictly used to add the hydraulic oil to the oil tank.

- Strictly filter the hydraulic oil and maintain regularly sufficient oil volume.

- Fill the oil immediately when it is insufficient.

- Clean the vertical metal baler’s oil tank and replace it with new oil every half a year.

- The first cleaning and oil filtration should not exceed one month.

- New oil that has been used once can only be used again after strict filtration.

- The lubricating parts of this vertical baler machine should be filled with lubricating oil at least once per shift as required.

- Clean the sundries in the material box in time.

- Do not start the machine without learning and understanding its structure, performance and operation procedures.

- In case of serious oil leakage or abnormal phenomena during operation, stop the machine immediately.

- Analyze the causes and eliminate the faults.

- Forced operation with fault is not allowed.

- During the operation of the hydraulic vertical metal baler, it is not allowed to:

- Repair or contact the moving parts.

- Press materials in the material box with your hands or feet.

- When adjusting the pump, valve and pressure gauge, it must be carried out by experienced technicians.

- If a pressure gauge is found to be faulty, it should be checked or replaced immediately.

- You should formulate detailed maintenance and safety operation procedures according to the specific situation.

Contact us for waste recycling solutions!

Are you looking for cost-effective solutions for waste metal recycling? We have vertical metal baler and horizontal metal baler machine to benefit your business.

If interested, contact us now and we’ll provide the best solution for you!