Hydraulic Baler Machine for Waste Paper

Hydraulic Baling Press | Vertical Baler

Hot selling models: SL-30T, SL-60T, SL-80T

Features: wide applications, customization, cost-effective price

Applicable materials: waste paper, waste cardboard, clothes, sawdust, hay, straw, coconut shells, cotton, aluminum cans, PET bottles, drums, etc

Related equipment: fully automatic horizontal baler machine for waste recycling

Vertical baling press is designed to efficiently compact materials such as waste paper into bales through its powerful hydraulic system. By using this hydraulic baling press machine, not only is storage space optimized, but transportation to recycling facilities is also facilitated. Our machines are available in a variety of models, 30T, 40T, 50T, 60T, 80T, 100T, etc. to meet your different needs.

Besides, our vertical baler is also popular for its performance among customers all over the world, such as Thailand, Vietnam, Gabon, Algeria and so on. Welcome to contact us for more details!

Why use the vertical baling press for recycling?

The use of a vertical baler for recycling offers a compact and efficient solution to manage recyclable materials. This equipment compresses materials like paper, cardboard, and plastics into dense bales, optimizing storage and transportation. With its hydraulic mechanism, it simplifies waste handling, reduces logistics costs, and promotes sustainable waste management practices.

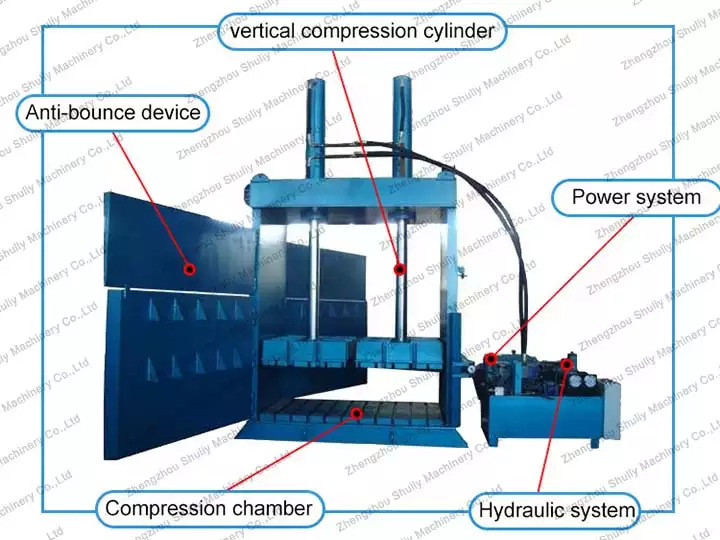

Components of hydraulic baling press

Our vertical baling press machine consists of hydraulic cylinders, anti-bounce device, power system, and compression chamber. Actually, the vertical baler structure is simple to understand, and you can operate the machine very easily.

Wide applications of vertical baling press compactor

This vertical baling press can bale and compress a lot of waste materials in addition to paper. Like, aluminum cans, cardboard, clothes, fibers, sawdust, wool, cotton, hay, straw, plastic bottles, coconut shells, agricultural waste, oil cans, garbage cans, and more.

Features of vertical baler

- Compact design: The vertical baler is designed to take up minimal floor space, making it suitable for a variety of environments, including businesses, warehouses and recycling centers.

- Multifunctional: Hydraulic baling press can handle a wide range of recyclable materials such as cardboard, paper, plastics, textiles and more, making it suitable for a variety of waste recycling.

- Customizable bale sizes: Our vertical baling press allows bale sizes to be adjusted to meet different recycling needs and optimize transport efficiency.

- Durability: High-quality construction and components ensure the longevity and reliability of the vertical baler, even under heavy use.

- Cost savings: By reducing the volume of waste and optimizing transportation, the hydraulic baling press can result in significant savings in waste management costs.

Other baling equipment for waste paper recycling

In addition to vertical balers, another essential type of baling equipment for waste paper recycling is the horizontal baler, also known as a horizontal waste paper baler.

The horizontal baler operates differently than the vertical baling press. Instead of compressing material vertically, this baler compresses waste horizontally to form larger, denser bales. This design is especially useful when dealing with large quantities of waste material. Horizontal balers are typically used in industries that need to efficiently process large quantities of paper, cardboard, and other recyclable materials, such as paper mills, printing and packaging, supermarkets and distribution centers, corrugated box manufacturers, and large recycling facilities.

Technical parameters of vertical baling press machine for sale

| Model | Electric power(kw) | Cylinder | Dimension(mm) | Packing size(mm) | Oil pump |

| SL-30 | 11 | 115 | 1650*850*2700 | 1000*600*800 | 532 |

| SL-60 | 15 | 160 | 1200*800*1000 | 1200*800*1000 | 563 |

| SL-80 | 18.5 | 180 | 1700*2100*3300 | 1200*800*1000 | 563 |