Advantages of double shaft crusher blades

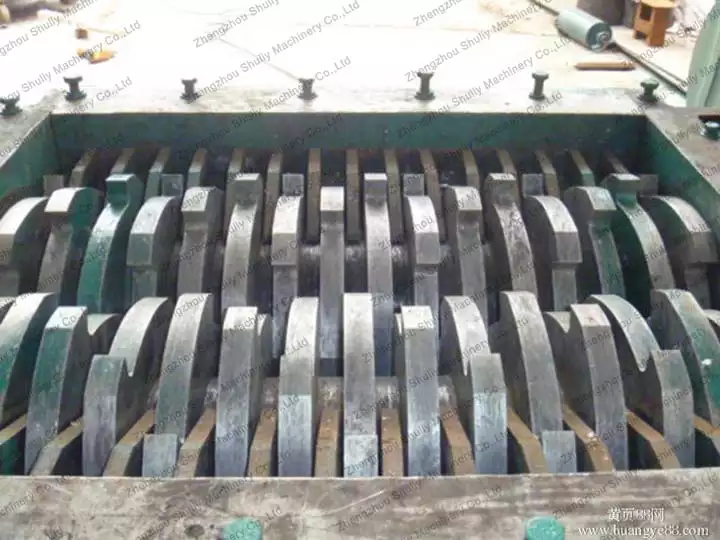

As an efficient material handling equipment, the blades of the double shaft crusher play a vital role in the whole shredding process. Through precise design and professional processing, twin-shaft shredder blades have a number of superior features that make them ideal for use in a wide range of industries. Let’s take a closer look at these advantages and see what makes them stand out in the shredding process, increasing efficiency and ensuring reliability.

High-efficiency shredding capacity

Twin-shaft shredder blades are precision designed and crafted to provide the excellent shredding capability. They can quickly shred various materials such as metal, plastic, paper, etc. into small pieces and improve processing efficiency.

Strong wear resistance

The blade is made of high-strength alloy steel, which has excellent wear resistance. Whether processing scrap metal or plastic, the blades stay sharp for a long time and are not easily worn, reducing the frequency of blade replacement

High reliability

Shuliy double shaft crusher blades are precision crafted and have a stable structure and robust connections. This gives the blades excellent reliability under high loads and enables long and stable operation, reducing breakdowns and downtime.

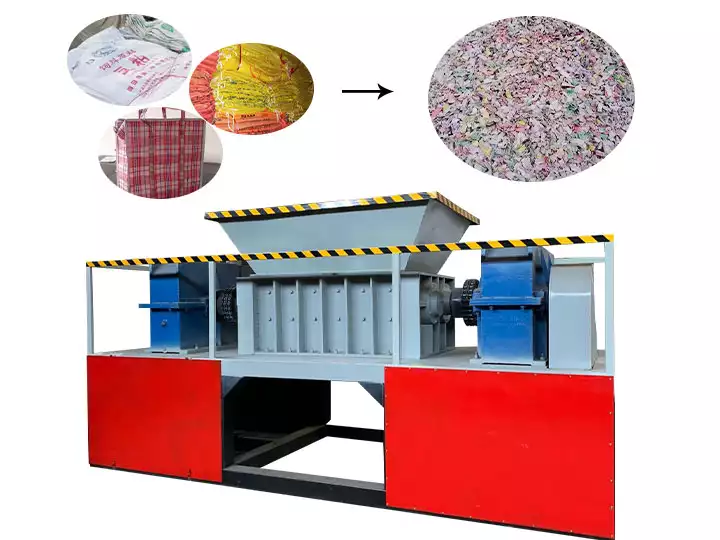

Multi-functional applications

Double-shaft shredder blades can adapt to the processing needs of a wide range of materials. Whether processing scrap metal, plastic, textiles or wood, the blades can effectively shred and crush to meet the needs of different industries.

Safety protection measures

The blades are installed in the sealed cavity of the double shaft crusher, effectively reducing the risk to the operator. The machine is equipped with safety guards, such as safety switches and guards, to ensure safety during operation and protect the operator’s physical safety.