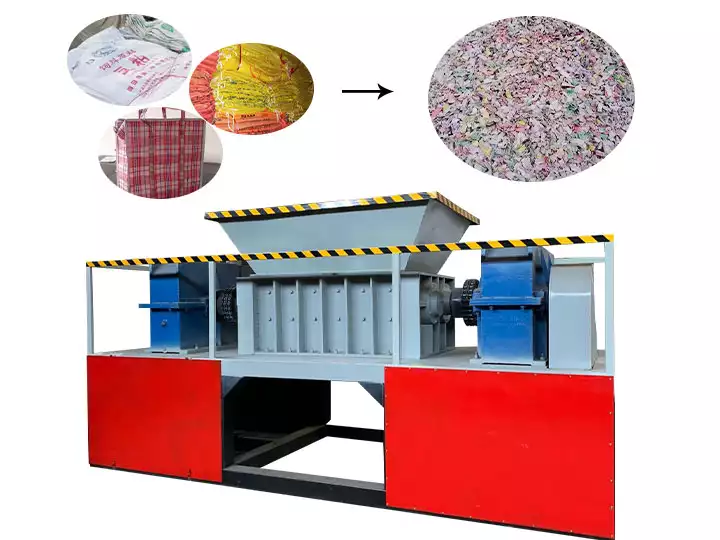

Double Shaft Plastic Shredder Machine for Crushing Waste Plastics

Plastic Crusher | Dual Shaft Shredder

Machine brand: Shuliy

Machine name: Double shaft plastic shredder

Advantages: Long service life, good quality blades for shredding, high-performance reducer

Service: After-sales service, customization, online guidance, etc

Warranty period: 1 year

Spare parts: Blades, blade plate

Plastic shredder machine is to crush various waste plastics like PET bottles, plastic bags, films, etc. into small pieces for recycling. This machine is a double-shaft shredder, with wide applications, long service life and low maintenance.

The plastic waste shredder machine reduces the volume of plastic waste and facilitates the subsequent granulation process. With the boost of the environmental industry, many related companies are equipped with dual shaft shredder to shred plastic waste for recycling. If interested, welcome to contact us for more machine details.

A brief introduction to the plastic shredder machine

The plastic shredder machine is a roll-cut shredder that rips waste materials through the shearing, tearing, and squeezing of rolling blades with hooks.

The industrial plastic crusher (also known as double shaft plastic shredder) is mainly used for preliminary crushing, suitable for all kinds of bulk solid materials, refractory materials, plastic containers, and other plastic products. Strong cutting ability, high production efficiency, long service life, and wide application range are all the advantages of the plastic shredding machine.

Technical parameters of dual shaft shredder for plastics

Model SL-400 parameters:

Capacity: 0.5-1t/h

Voltage: 440V, 60HZ, 3phase

Power: 7.5KW*2

Blade thickness: 20mm

Blades quantity: 20pcs

Blade plate material: 9CrSi

Equipment size: 2000*1100*1620mm

Weight: 1100kg

Application scope of the plastic film shredder

The plastic shredder machine can be used for the crushing and recycling of waste plastics such as boxes, thin pipes, blow-molded parts, bottles, shells, etc. Or, it’s as an auxiliary machine for the injection molding machine to re-grind the nozzle materials or defective parts of the injection molding machine.

Its application range involves bulky pipes and profiles, large blow-molded parts, and other production waste such as PET bottles, PE film, plastic film bales, plastic drums, plastic sheets, plastic boards, plastic floors, containers, and so on.

The plastic bags shredder can also process the following materials:

- Scrap metal: paint buckets, scrap steel, scrap iron, scrap aluminum, metal briquettes, etc.

- Timber: lumber, tree roots, wooden pallets, scrap furniture

- Rubber: tires, truck tyre, car tyre

- Cardboard, carton, paper, books

- Waste household appliances, vehicles: TV sets, washing machines, motorcycles, cars, bicycles, etc.

- Electrics: cables and wires, circuit boards

- Waste clothes or fabrics

Outstanding features of the plastic shredder machine for sale

- Compared with the single-shaft plastic shredder, this plastic crusher has a wider range of applications, and can handle larger volumes of raw materials and higher efficiency.

- Thick and heavy moving knives: all knives are cast with alloy steel, sturdy and long service life with high crushing efficiency.

- Our dual shaft shredder has the characteristics of low speed, high torque, low noise, and dust that can meet environmental protection standards.

- The frame plate is thick, resistant to high torque and very strong.

- Easy to adjust, low maintenance cost and very durable.

- Adopt microcomputer automatic control, set start, stop, reverse and overload automatic reverse control functions.

- The thickness of the tool and the number of claws can be changed according to different materials, and the size of the discharged particles is uniform.

- Large feeding port, which also can be customized.

How does the plastic lumps shredder work?

The material enters the inside of the shredding box through the feeding system, and the box carries the shredding blade. The material is shredded into small pieces after the combined action of two rows of shredding blades, such as tearing, squeezing, and shearing, and discharged from the lower part of the plastic shredder machine.

Precautions for using the plastic shredder machine

- Before starting the plastic shredder machine, it needs to strictly check whether the installation of each component is reasonable and whether the bolts are loose.

- The twin shaft shredder should be preheated and idling before starting up. This step can improve the working state of the equipment and prolong its service life.

- The plastic crusher should be regularly maintained for smoothness, but it should be noted that the lubricating oil should not be added too much at one time.

- After the operation, the broken plastic should be completely emptied, and then the machine should be closed. The state of the blade should be checked in time, and the worn blade should be polished and replaced in time to prevent damage to other parts of the equipment caused by the wear of the blade.

- During the feeding process, you should add suitable crushing materials according to the model, and adding hard materials that exceed the crushing capacity may cause damage to the blade and motor, resulting in equipment failure.

Start your plastics recycling now!

If you want to do plastic-based waste recycling, our dual-shaft plastic crusher is your first choice. Come and contact us, we will provide you with the best offer according to your needs.