Export model 4-8 spiral rebar forming machine to Russia

The customer is an international trading company based in Russia, specializing in serving construction contractors and rebar processing plants. To meet the demand for rebar coils from their downstream customers, they decided to purchase a spiral rebar forming machine as part of the rebar processing equipment.

Clear customer demands

The customer’s requirements were very clear: a 5mm rebar diameter and different loop diameters and loop spacing requirements. Details are as follows:

| Loop diameter | Loop spacing requirement |

| 27.5mm | 50±2mm |

| 40mm | 50±2mm |

| 44mm | 50mm |

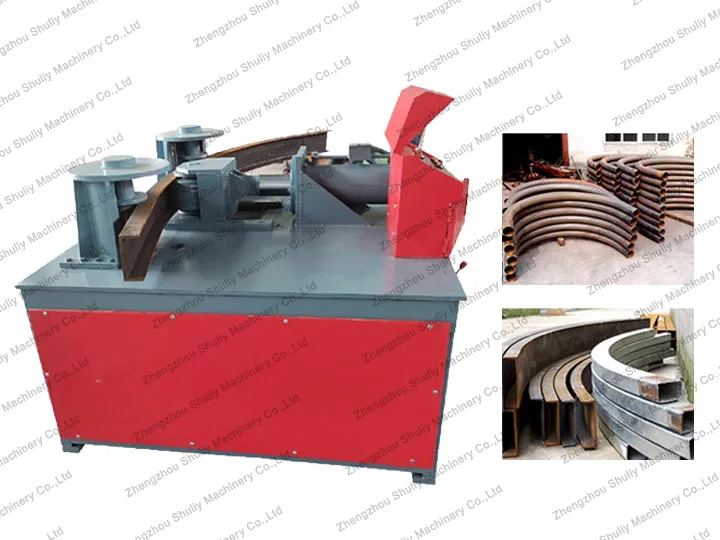

Shuli Machinery provided a 4-8 steel bar looping machine based on these parameters, along with a 4-ton wire feeding frame, ensuring the equipment meets the customer’s efficient looping needs. The spiral rebar forming machine operates on 380V, 50Hz, three-phase power, fully compliant with local usage standards.

Why choose Shuliy spiral rebar forming machine?

The customer chose Shuli Machinery based on the following key factors:

- Stable performance: the rebar circle making machine precisely controls diameter and coil spacing to ensure processing quality.

- Customized services: parameters are adjusted according to customer requirements to meet actual engineering needs.

- Comprehensive services: Shuliy not only provides equipment but also handles transportation and technical support, alleviating customer concerns.

- Extensive international experience: exported to over 80 countries, Shuliy is trusted by global customers.

Through this collaboration, the spiral rebar forming machine not only meets the processing needs of the Russian customer’s downstream clients but also provides strong support for expanding the rebar products market. Shuliy Machinery will continue to offer customers efficient and reliable rebar processing solutions.