Máquina enfardadeira hidráulica para resíduos de papel

Prensa enfardadeira hidráulica | Enfardadeira Vertical

Hot selling models: SL-30T, SL-60T, SL-80T

Features: wide applications, customization, cost-effective price

Applicable materials: waste paper, waste cardboard, clothes, sawdust, hay, straw, coconut shells, cotton, aluminum cans, PET bottles, drums, etc

Related equipment: fully automatic horizontal baler machine for waste recycling

Vertical baling press is designed to efficiently compact materials such as waste paper into bales through its powerful hydraulic system. By using this hydraulic baling press machine, not only is storage space optimized, but transportation to recycling facilities is also facilitated. Our machines are available in a variety of models, 30T, 40T, 50T, 60T, 80T, 100T, etc. to meet your different needs.

Besides, our vertical baler is also popular for its performance among customers all over the world, such as Thailand, Vietnam, Gabon, Algeria and so on. Welcome to contact us for more details!

Por que usar a prensa enfardadeira vertical para reciclagem?

A utilização de uma enfardadeira vertical para reciclagem oferece uma solução compacta e eficiente para gerenciar materiais recicláveis. Esse equipamento comprime materiais como papel, papelão e plásticos em fardos densos, otimizando armazenamento e transporte. Com seu mecanismo hidráulico, simplifica o manejo de resíduos, reduz custos logísticos e promove práticas sustentáveis de gestão de resíduos.

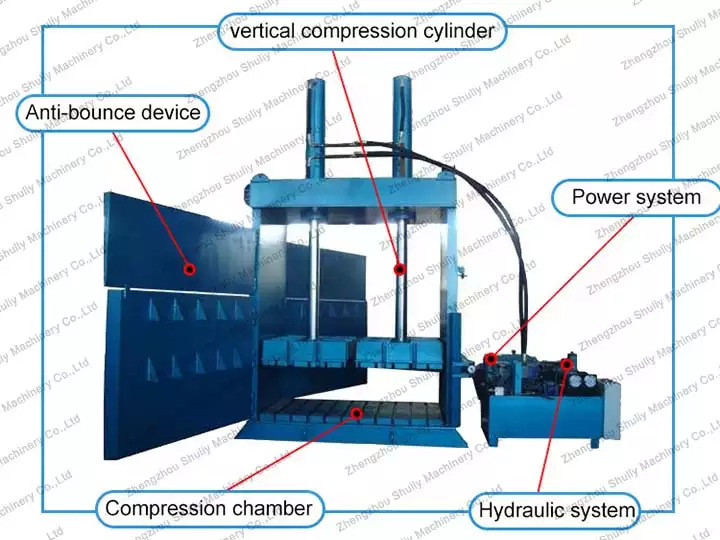

Componentes da prensa enfardadeira hidráulica

Nossa prensa enfardadeira vertical consiste em cilindros hidráulicos, dispositivo anti-ressalto, sistema de energia e câmara de compressão. Na verdade, a estrutura da enfardadeira vertical é simples de entender e você pode operar a máquina com muita facilidade.

Amplas aplicações de compactador de prensa enfardadeira vertical

Esta prensa enfardadeira vertical pode enfardar e comprimir muitos resíduos além do papel. Como latas de alumínio, papelão, roupas, fibras, serragem, lã, algodão, feno, palha, garrafas plásticas, cascas de coco, resíduos agrícolas, latas de óleo, latas de lixo e muito mais.

Características da enfardadeira vertical

- Design compacto: A enfardadeira vertical foi projetada para ocupar um espaço mínimo, tornando-a adequada para uma variedade de ambientes, incluindo empresas, armazéns e centros de reciclagem.

- Multifuncional: A prensa enfardadeira hidráulica pode lidar com uma ampla variedade de materiais recicláveis, como papelão, papel, plástico, têxteis e muito mais, tornando-a adequada para uma variedade de reciclagem de resíduos.

- Tamanhos de fardos personalizáveis: Nossa prensa enfardadeira vertical permite que os tamanhos dos fardos sejam ajustados para atender às diferentes necessidades de reciclagem e otimizar a eficiência do transporte.

- Durabilidade: A construção e os componentes de alta qualidade garantem a longevidade e a confiabilidade da enfardadeira vertical, mesmo sob uso intenso.

- Economia de custos: Ao reduzir o volume de resíduos e otimizar o transporte, a prensa enfardadeira hidráulica pode resultar em economias significativas nos custos de gestão de resíduos.

Outros equipamentos de enfardamento para reciclagem de resíduos de papel

In addition to vertical balers, another essential type of baling equipment for waste paper recycling is the horizontal baler, also known as a horizontal waste paper baler.

The horizontal baler operates differently than the vertical baling press. Instead of compressing material vertically, this baler compresses waste horizontally to form larger, denser bales. This design is especially useful when dealing with large quantities of waste material. Horizontal balers are typically used in industries that need to efficiently process large quantities of paper, cardboard, and other recyclable materials, such as paper mills, printing and packaging, supermarkets and distribution centers, corrugated box manufacturers, and large recycling facilities.

Parâmetros técnicos da prensa enfardadeira vertical para venda

| Modelo | Energia elétrica (kw) | Cilindro | Dimensão (mm) | Tamanho da embalagem (mm) | Bomba de óleo |

| SL-30 | 11 | 115 | 1650*850*2700 | 1000*600*800 | 532 |

| SL-60 | 15 | 160 | 1200*800*1000 | 1200*800*1000 | 563 |

| SL-80 | 18.5 | 180 | 1700*2100*3300 | 1200*800*1000 | 563 |