Mesin pembalut skrap logam SL-100T dijual kepada pusat kitar semula sisa Albania

This Albanian client operates a comprehensive scrap recycling center specializing in the recovery and processing of various metals, including aluminum, copper, and iron. Due to the diverse types, large volumes, and logistical challenges of storing and transporting scrap metals, the client urgently required a metal scrap baler machine capable of efficient baling output.

This solution would enhance overall recycling efficiency, conserve warehouse space, and meet downstream customers’ demand for uniformly packaged materials.

Recommended equipment & selection

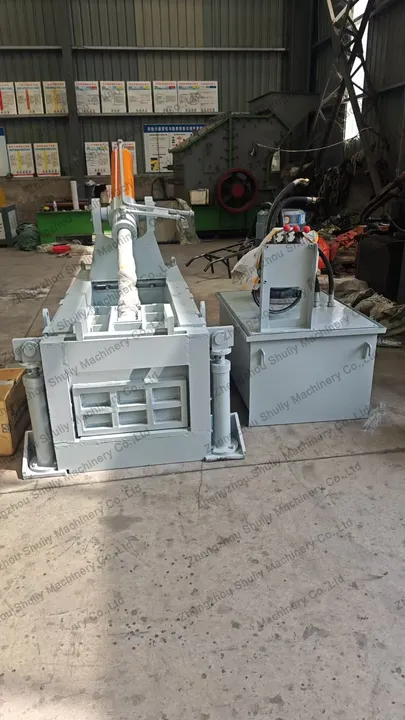

After multiple discussions and comparisons, the client ultimately chose our recommended Model-100 hydraulic metal baler. This 100-ton baler is a manual front-discharge model, featuring a hydraulic lift door. It’s suitable for processing various metal scrap materials.

Key specifications of this metal scrap baler machine:

- Pressure: 1000kN

- Stroke: 1250mm

- Kuasa: 15kW

- Normal pressure: 25MPa

- Chamber dimension: 1000×500×500mm

- Finished bale dimension: length 500mm, height 250mm, thickness 20-500mm

- Single cycle time: approx. 80-100 seconds

- Bale discharge method: hydraulic front discharge

- Operation: manual valve control

- Voltage requirement: 400V, 50Hz, three-phase power

This machine features powerful compression capability and flexible operation modes, making it particularly suitable for daily batch processing of metals at medium-sized recycling centers.

Customer concerns

During communication, customers primarily focused on the following points:

- Multi-metal compatibility

- Whether it can simultaneously process metals of varying hardness and volume, such as aluminum, copper, and iron.

- Baling efficiency

- Can it meet daily high-volume scrap processing demands with an 80-100 second cycle time?

- Finished bundle specifications

- Whether the strapped bundles facilitate storage, transportation, and sale.

- Operasi yang mudah

- Manual valve operation ensures simplicity and quick employee training.

- Stability and after-sales support

- Clients prioritize equipment reliability and inquire about remote guidance and after-sales guarantees.

Actual application results

Upon arrival at the Albanian customer’s plant, the metal scrap baler machine was promptly put into operation. Customer feedback:

- Scrap aluminum, scrap iron, and copper ingots are all efficiently compressed into uniformly sized metal bales.

- The front-discharge design simplifies operation, reduces labor requirements, and ensures smooth bale ejection.

- Finished metal bales feature consistent dimensions, facilitating loading and sales.

- The machine operates stably with a robust hydraulic system, meeting daily high-volume processing demands.

The client expressed high satisfaction with this 100-ton hydraulic metal baler. They said,

“The equipment significantly enhances scrap metal recycling efficiency, reduces labor costs, and optimizes storage and transportation processes.”

Are you also searching for a baler to handle various metal scrap materials? Tell us your requirements, and we’ll provide tailored solutions based on your specific needs.